I've been quiet.

Here's why:

My 2004 DD coupe

a few days later....

I had the swirl... running with an LSJ/L61 hybrid engine.

The skwirl has a working drivetrain, but is not everyday friendly.

Blue was an everyday friendly car without a working drivetrain.

some pillaging needed to happen.

special tool I made to get the pesky L61 out of Blue.

with the L61 out, and the 2005 L61 head off the LS61 sold to a friend, I decided to reunite the LSJ head to the LSJ block, and run a straight up LSJ swap in Blue.

setup:

2005 LSJ ecotec engine 2.0L

-arp headstuds

-cometic headgasket

-balance shaft delete

2005 F23 getrag transmission

-LSJ clutch

-LSJ trans spacer

first I needed to figure a better way to mount the crank shaft position sensor

this little beauty puts the sensor in a nice safe location, and also replaces the water pump access cover. Nice, secure, and stock.

then I needed to modify the intake manifold/ head in order for them to marry together without troubles

drilled and tapped the PCV port on the LSJ head for NPT threads (I forget if its 1/4 or 3/8)

stock L61 intake manifold bolts are too small for the LSJ head

size comparison

LSJ intake manifold bolts won't fit through the LE5 intake manifold

so I ordered some special bolts and knocked out the brass sleeves in the intake manifold in order to get them to marry.

I also had to clearance the intake manifold around the PCV port

I then had to weld shut the stock PCV gasket on the LE5 manifold

mock up

LSJ in the car

beginning to fabricate the cam sensor block off (keep this in mind for later..)

LSJ ignition cover

time to abrasive-blast

after a few minutes, no more ugly spray paint

now that its clean, time for some machining

all done

here's why

the LSJ ignition cover will hold the L61 ignition down in place in the LSJ valve cover.

fixing aeromotive's fuel pressure regulator (it's 1/16NPT... I needed 1/8NPT)

machining some more parts

what the hell is this for....

intercooler and oil cooler mounted up to plate that bolts to the bottom of the radiator core support

mounted up

after a tiny bit of bumper trimming, fits like a god damn glove

ended up having to use an aftermarket crank pulley so the trigger ring would sit flush. here's a nice view of the VR sensor bracket I made

top down view showing clearance

from the bottom up

I turned gay and made 1" thick rear wheel spacers. (with the saturn disc brackets, I have a 3" wider track in the rear)

before space

after space

another shot.. yea my tires are narrow.. time to upgrade.

custom fabricated battery tray

mounted up

time to do the pesky exhaust....

3" front to rear.

all v-band

all stainles steel

magnaflow spun cat

magnaflow resonator

magnaflow muffler

muffler bracketry (muffler is fixed in place, flex joint is in the downpipe)

mounted

I used a prebent cat-back system from Mandrel Exhaust Systems and was severely disappointed with the fit. After cutting the pipe and reshaping it a bit I got it to fit beautifully. I have over 1/2" of clearance on the torsion beam with 3" exhaust piping. Way better than the skwirl ever had.

ground clearance isn't bad either

exhaust finished early in the morning fog

F it... I'm stealing the manual brake setup from the skwirl too....

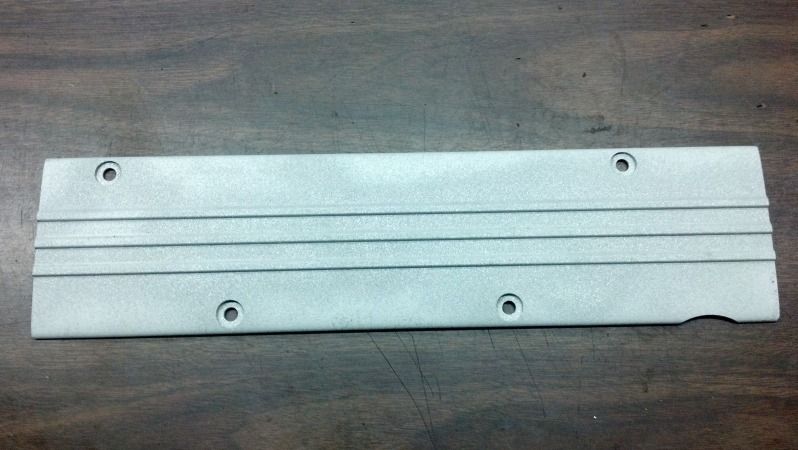

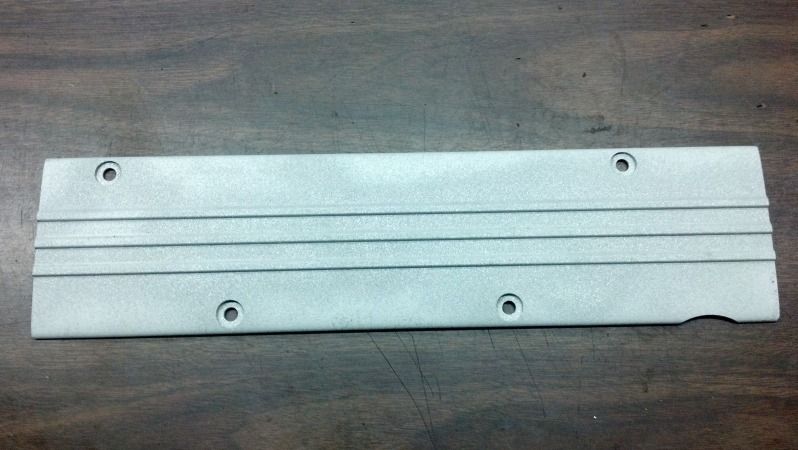

but I'm going to remake the adapter plate so that it actually FITS this time

looks a lot better with that little bevel on the edge

looks a lot better with stainless steel hardware too

painted and mounted

what to do what to do...... you know what? I don't like my cam sensor block off plate....

I think I'll put the PS pump on the exhaust cam instead of the intake cam.....

gonna need this to extend the hex drive a little bit (this is before I trimmed it down)

time to clean up that aluminum piece...

again, stainless hardware. countersunk the mounting holes so they didn't interfere with the pump.

F-ing beautiful

sooooo much room for induction now when I throw the turbo on it

manual brakes are a necessity for moving the PS pump

almost done.....

I'm a few days away from completing the car and starting it up.

comments welcome.