First off, this is gonna be a *slow* and drawn out process, mainly because I work out of state 3 weeks a month, so there will be times where not much is done, but I will update as I get things accomplished.

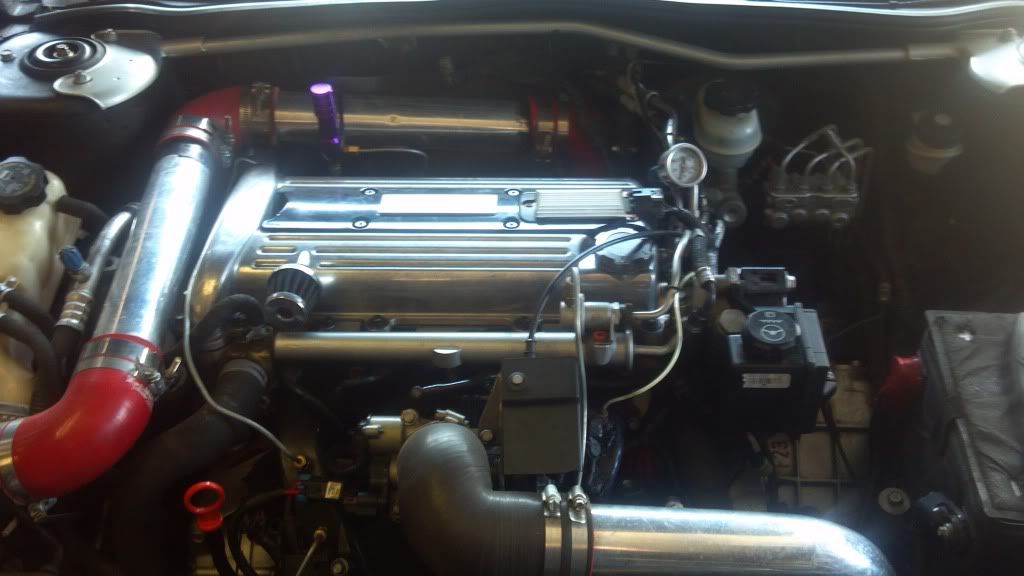

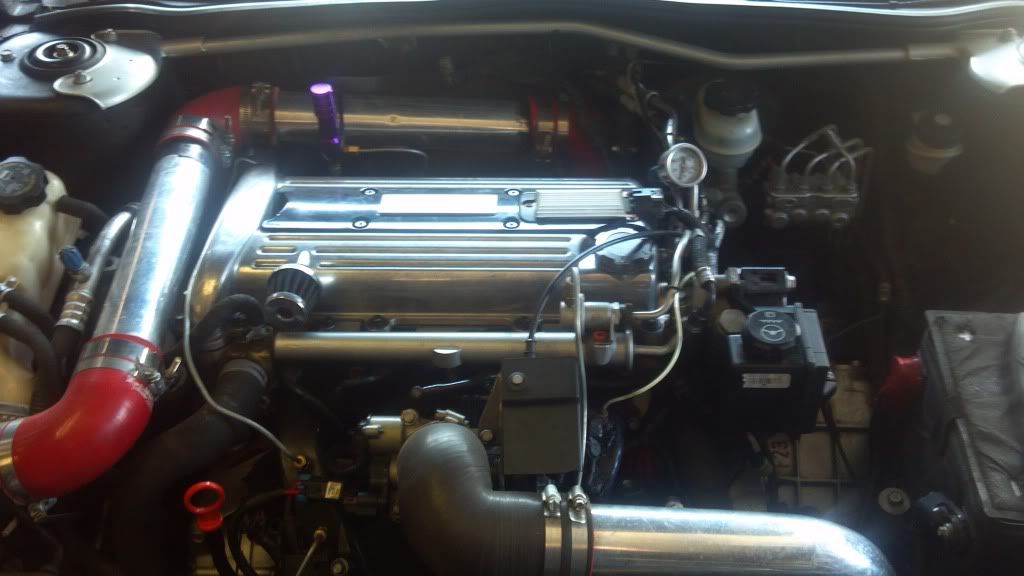

I'm going with a completely new setup. The only things that I am reusing are the turbo it'sself (modified), and the intercooler. The old setup was ugly as all hell, but it was functional and never gave me any problems.

I'm getting rid of the old intercooler piping, wastegate, wastegate adapter, and manifold. They have served me well, but it's time for an upgrade. Now just to rip everything off.....

WOW!!! There is alot of room in the engine bay now!!! I'm going to be doing a thorough wire tuck, and possibly relocating the battery to the fenderwell.

I've already got a nice stockpile of parts just waiting to get installed. First off, I have a TTR manifold that is going to be going on. It's been heavily modified from original though. It has been CNC ported, polished, and an external wastegate v-band flange has been welded on. Before it's installed though, I'm having it sent out to be Jet-Hot ceramic coated.

By the way, my machinist made a custom CNC program for porting the manifold, so if anyone needs any similar work done, just contact me.

And of course, the manifold wouldn't be complete without the nice, shiny and new 38mm v-band wastegate!!!

My Hallman boost controller will be reinstalled, with the remote adjustment setup so I can tinker with the boost level from inside the car.

New stainless steel braided oil line, never too much lubrication!

And my favorite part so far. I've always had problems with the downpipe gasket leaking, so I had my machinist make a flange to bolt to my turbine housing to convert it to a V-band style outlet. It is CNC machined out of 1/2" stainless steel, and is absolutely amazing!!!

On the lathe to make sure everything is as smooth as possible.

The 12MM stainless allen bolts are countersunk into the flange for clearance.....

With the complete V-band clamp setup installed, I have just enough clearance and everything fits together beautifully.

Not done yet!!! I had the turbo housing machined, ported, polished, and threaded for the new flange as well.

The exhaust inlet gasket matched, smoothed, and blended.

The exhaust outlet on the housing was enlarged quite a bit to match the new flange, and it's a perfect match

Yes, that's a mirror finish you see on the exhaust outlet coming from the turbine shaft!!!

You can also see the stainless steel M12X1.5mm heli-coil inserts for the flange bolts.

I just finished media blasting the turbine housing, and it will be sent out along with the manifold for Jet-Hot Ceramic coating very soon!!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

As always, comments/criticisms/flaming/hating/suggestions are welcomed and appreciated. If anyone has any input or ideas let me know. I'm early enough into the build to change ideas on a whim.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

I got no beef, keep the updates coming

Yup looks like its gonna be a really nice setup man!! Keep up the great work..

Looking good. You ever tuck that intercooler up so its not hanging so low?

"Oil Leak ? What oil Leak ? Oh, Thats Just The Sweat From All The HorsePower!!"

I'd like to make upgrades like this but I'm too busy blowing up engines...

These forged engine cost a lot...

Looks great man nice new set up so far goin in....

Thanks for the comments people! I have an insane amount of time and money into this re-build so far. Mainly the small stuff such as flanges, machining, ect. I'm going with a 3" V-band downpipe as well, should be good for easy removal if need be, and again no chance of leaks.

DSMskyline wrote:Looking good. You ever tuck that intercooler up so its not hanging so low?

Of course. It was only low like that for lack of time before the first track day, and a dose of laziness. It's been tucked up for over a year now.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

What turbo is that?? It looks a lot like the Hahn 16g I am using

Roofy wrote:

And my favorite part so far. I've always had problems with the downpipe gasket leaking, so I had my machinist make a flange to bolt to my turbine housing to convert it to a V-band style outlet. It is CNC machined out of 1/2" stainless steel, and is absolutely amazing!!!

That looks a lot like what Fetter made for me. 3 bolt flange with a 2.5 V-band welded to it

Roofy wrote:

Not done yet!!! I had the turbo housing machined, ported, polished, and threaded for the new flange as well.

The exhaust inlet gasket matched, smoothed, and blended.

The exhaust outlet on the housing was enlarged quite a bit to match the new flange, and it's a perfect match

Nice work....I have been meaning to do the same to my housing

Edited 1 time(s). Last edited Sunday, July 08, 2012 2:27 PM

Jason

99 Z24

LG0/LD9 for Life

10 Year Bash Veteren

Blwn LD9 wrote:What turbo is that?? It looks a lot like the Hahn 16g I am using

That's correct!!! Well... kinda.

It used to be a Hahn 16G, but I modified it and upgraded it to a hybrid 20G Mitsu turbo. Pretty simple to do actually.

The recessed surface is smaller on the 16G turbo where the compressor wheel sits.

The recessed surface was simply machined larger to have the same corresponding amount of clearance while using the 20G wheel.

My nice new 20G upgrade parts courtesy of Kinugawa Turbo.

Visual size differences between the 16G and 20G compressor wheels and housings.

The nice thing about Mitsubishi turbos is that they are component balanced, meaning I was able to assemble the unit as-is without rebalancing. Although I did throw a quick rebuild on it when I upgraded, but so far, 8,000+ miles and no problems!!!! I originally bought it used off of Ebay, and it has been rebuilt by me 3 times. Once when I first got it, again when I upgraded to the 20G setup, and again last month when I started the teardown. Maybe not necessary, but as cheap and easy as the Mitsus are to rebuild, I might as well.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Was getting that v-band made cheaper then just buying

this?

______________________________________________________________________________________________

~Using nitrous is like having sex with a hot chick with an STD, you wanna hit it, but your afraid of the consequences.~

Mike wrote:Was getting that v-band made cheaper then just buying this?

I actually ordered, that flange a while back, but it was the wrong size and wouldn't work for what I needed done. Hence, why I went custom.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Lovin the re-build plans, keep ti up bud!

Roofy wrote:Mike wrote:Was getting that v-band made cheaper then just buying this?

I actually ordered, that flange a while back, but it was the wrong size and wouldn't work for what I needed done. Hence, why I went custom.

I did not know about that flange when I had mine made.

I found this one from

Himni Racing or this one

Turbo fittings.com

In the end I had Fetter make one for me to use a 2.5" v-band instead of a 3"

Jason

99 Z24

LG0/LD9 for Life

10 Year Bash Veteren

Yeah all the ones available kept the smaller original size exhaust outlet. I wanted to have the larger outlet. With no big transitionfrom different pipe sizes.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

love all the detail work, man.

oh, and i loved that you used hard lines on the boost controller.. even if it was the old setup. that was neat. so sick of seeing setups with rubber lines where people just lay them down or zip tie em up.

I choose the technology built for land speed records... not the technology built to save on emissions and gas mileage.

ALL my vacuum/boost lines are hard bent metal. Pretty simple, I just used 3/16" brake line and 3/16" to 1/8"NPT compression fitting brass adapters to tie it all together. I like it because there is no chance of swelling, leaks, or degrading over time. Plus, noone else has done anything like it that I have seen.

I will be using the same line setup with my new build as well.

You can see the fittings and polished lines in this pic from my old setup.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Just a small update. My new RFL blow off valve is ordered, and my turbo pieces are in the process of being jet hot ceramic coated as we speak.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

New RFL blow off valve has arrived.

And my manifold and turbo housing are back from Jet-Hot. I went with the Extreme 2500 coating. Crinkle black on the manifold, and light gray crinkle finish on the turbo housing it'sself.

My apologies for the low quality pix.

And my 3" v-band setup for the bottom part of my downpipe is ordered and on it's way as well!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Nice man, how much did the Jet hot run you?

~2014 New Z under the knife, same heart different body~

______________________

WHITECAVY no more

2012 numbers - 4SPD AUTOMATIC!!

328 HP

306 TQ

Brand new suspension is here! Tokico D-spec adjustable struts with 1.4" lowering springs. I will be coupling these with the OEM solid strut mounts

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

My stainless steel 3" v-band flange just showed up. Wow, that was quick!!!!

WHITECAVY wrote:Nice man, how much did the Jet hot run you?

$410 shipped for both pieces to be coated.

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Currently #4 in Ecotec Forced Induction horsepower ratings. 505.8 WHP 414WTQ!!!

Currently 3rd quickest Ecotec on the .org - 10.949 @ 131.50 MPH!!!

Out of curiosity what did the vband cost you? Everything looks great.