Well, this car's been getting only 50 miles a year since 2006, after I built the engine, and head up. lowered compression for turbo, and even got a turbo cam, but the car sits today with no turbo. So, this year will be the year I focus on the car. I've been getting the car running reliably over the past month, and my eventual goal will be to run either a GT2871R 70 trim, or a T3/T40e hybrid 60 trim. Not sure on the manifold yet. As the title says, 250hp is my goal. I know it's possible on a 2.2. That's already been proven, but it's on the upper limit, so I still real it's gonna be a lot of work. Anyways, I've already fixed a problem with the wiring under my dash which was affecting my starter. I wasn't able to start the car, but i've got all that fixed now, so i'm driving it every day now. I've probably driver more in the past month in the sunfire than in the past 5 years combined. I found a radiator leak from a crack in the plastic end cap on the upper radiator. I tried to patch it with epoxy... that held while the engine temp was low, but didn't last when the engine was very hot. So, I've got a new radiator now.

On with the pics.

In this photo, you can see just how thin the stock radiator is when I hand used for scale. I debated with going with an upgrade, but I've read people say that cooling isn't really an issue with the stock radiator. Anyways, I guess we'll see. Plus I plan to use the trans cooler on the side to cool the oil.

250whp is the out limit?

250whp has been done on a stock motor you have a built motor. 400+whp has been done on a built motor, so you are fine. I think you could half ass it and make 250whp.

FU Tuning

FU Tuning

With that low of an hp goal why not use something smaller than a T3/T4oe 60 trim for faster spool?

Addicted to meth wrote:250whp is the out limit?

250whp has been done on a stock motor you have a built motor. 400+whp has been done on a built motor, so you are fine. I think you could half ass it and make 250whp.

You guys know I have a OHV 2.2 motor right? Only person I know making big numbers on one is juicedz4. But he's got way better fab skills than me. He's basically rebuilt the car and engine from scratch, and did it amazingly. As high as oem quality.

VTLoki wrote:Addicted to meth wrote:250whp is the out limit?

250whp has been done on a stock motor you have a built motor. 400+whp has been done on a built motor, so you are fine. I think you could half ass it and make 250whp.

You guys know I have a OHV 2.2 motor right? Only person I know making big numbers on one is juicedz4. But he's got way better fab skills than me. He's basically rebuilt the car and engine from scratch, and did it amazingly. As high as oem quality.

Ryan egleston is at 400, a lil over i think.

These cars arent as hard to make power out of em as the bandwagon says. Lol. Sure it isnt nearly as efficient in making power as others but its no slouch either.

When i look back i feel my build was half assed, lol... And it still impressed the hellout of me driving it... And ive driven pretty fast cars.

Mrs Jazer wrote:VTLoki wrote:Addicted to meth wrote:250whp is the out limit?

250whp has been done on a stock motor you have a built motor. 400+whp has been done on a built motor, so you are fine. I think you could half ass it and make 250whp.

You guys know I have a OHV 2.2 motor right? Only person I know making big numbers on one is juicedz4. But he's got way better fab skills than me. He's basically rebuilt the car and engine from scratch, and did it amazingly. As high as oem quality.

Ryan egleston is at 400, a lil over i think.

These cars arent as hard to make power out of em as the bandwagon says. Lol. Sure it isnt nearly as efficient in making power as others but its no slouch either.

When i look back i feel my build was half assed, lol... And it still impressed the hellout of me driving it... And ive driven pretty fast cars.

Hmm, good to know. I feel better now

now I just need to get this radiator replaced and locate where my ticking engine noise is from under partial throttle between 1500-2500 rpm. Above 3k and the noise is gone. The Ecu is registering it as knock and retarding the timing. It sucks...

What kind of rockers are you running in the motor? Also where does the noise sound like it's coming from?

JUCNBST wrote:What kind of rockers are you running in the motor? Also where does the noise sound like it's coming from?

i have ones like these.

http://www.compcams.com/information/products/rockerarms/magnumroller.asp It sounds like it's from the valve train. When It's not snowing out, i'm going to take the valve cover off and that area is going to be the first thing I look at. I checked them when I first got the car running a few months ago, and they were all tight, but it was when the car was hot. Should I check these when the engine is cold (maybe the parts shrink a little when not hot?)

oh, yah. And I have the 1.6 rockers.

More progress tonight. Got the new radiator installed. Took only 3 hour by myself. No leaks on the first fire up. Drove it for about 2 hours, and still no leaks. I think i'm good

now onto the pics.

I started by taking out the front cross member.

a pic showing the space between the air condenser, and radiator.

After lots of unbolting, and removing of connections, I was able to get the radiator to this point right before I pulled it out. This was a lot harder than the pictures show. Well, only to the extent that the tolerances are tight, so you've got to get everything in just the right spot.

The before bling, and after bling.

Yeah I know what motor your talking about.

Ryan made 276whp on a stock motor with boost. It comes down to tuning. He drove his car for like 2-3 years like that.

Now has a motor making 420whp on medium boost, and it can take more boost. I rode in the car and it is sick!!!!!

So your goal with a built motor is easy as long as you have good tuning and things are put together decent.

FU Tuning

FU Tuning

I'd check the valve train when cold, and idk the specs off hand for the pre 98 2.2's but make sure the valve lash is adjusted properly.

Looking forward to the build. Have you considered a T3 super 60 turbo?

Your gonna need to do a top feed conversion.....

P&P Tuning

420.5whp / 359.8wtq

QWK LN2 (P&P Tuning) wrote:Your gonna need to do a top feed conversion.....

Yup, I know. I already did that in 2005, right before I stopped working on it.

I've kinda been gone from the org since 2005,, so I didn't realize so many people had such good success with the ln2. I think I want to increase my goal to lower 300's for Hp.

Got my new PLX Devices Wideband and OLED gauge installed today. Here's some pics, and a video of me testing it on a bench. I don't have install pics thought. I love the fact that the gauge has a touch screen! COOL!!!

The brain box is so small, smaller than the picture makes it look.

Side view.

youtube video of initial power up of the Wideband.

http://youtu.be/qDrjdC-kZJM

On a side note, how do I put a video on the forum?

Ok, radiator problem solved. On to other problems. I've been trying to isolate some noise which I think is from the Valve train. When I used my computer to datalog, I noticed knock retard in the lower RPM range during this ticking noise i'm hearing. So, I began by adjusting the valve train. I opened it up, and found most of the rocker arms are loose. I tightened the ones that were loose and began a process where I would slightly turn the key to start it (with spark plug wires disconnected and fuel injectors disconnected), and then tighten the ones that were loose again. I did this for a while, and most were staying tight. I test drove it, and it seems a bit smoother, but I still can hear the noise. I still need to do another data logging session to see if it's retarding the timing still. It did feel like it had a lot more power.

All that said, I wanted to get everyone's opinions on some stuff I saw with the valve train when I was adjusting the valves.

Side view:

Other side view:

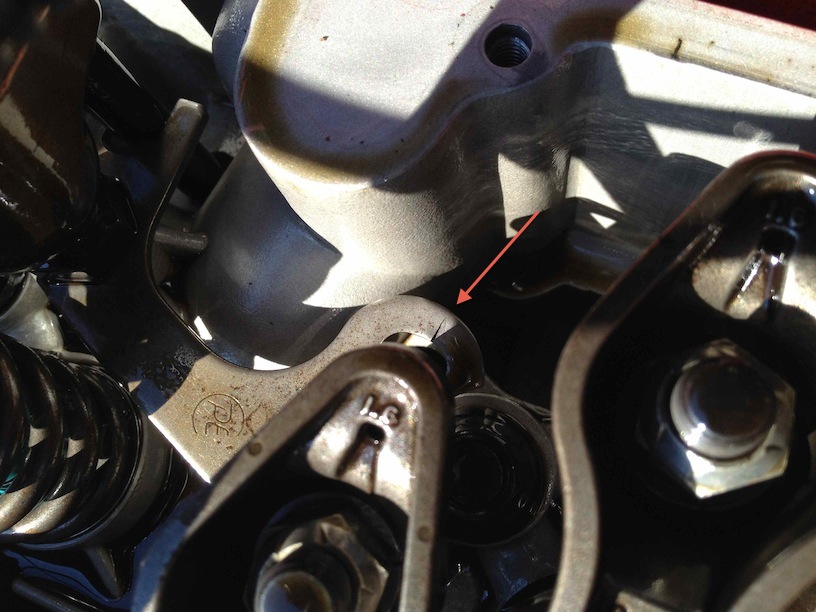

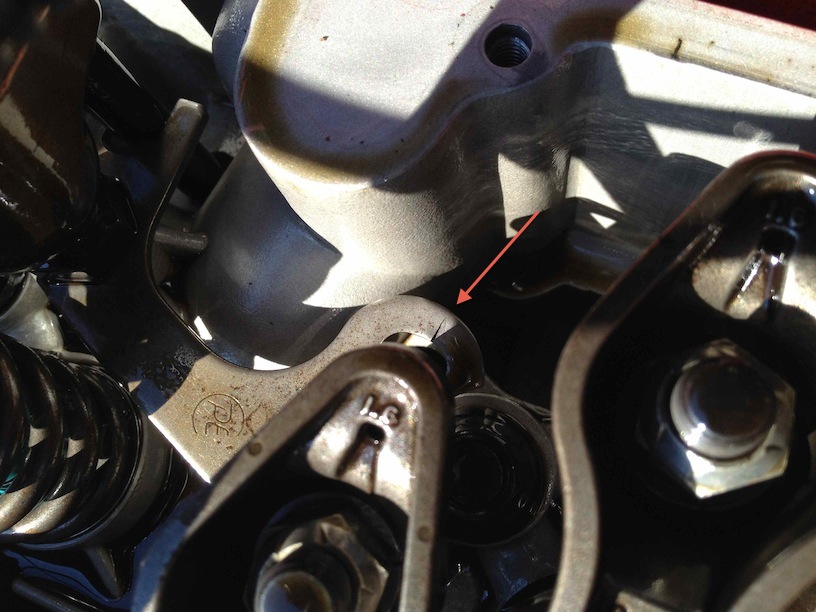

Ok, Here's where my concern starts. Is this normal?? I don't think so.

Could the problem be that the valve guide is a little cracked? allowing the pushrod to move to far one way, allowing the rocker to pivot?

Here's another item of concern. It looks like the pushrod is in contact with the openings in the cylinder head for the pushrods. How much clearance should there be here for the pushrods??

Should I just start with getting a new valve guide and see how things are after that?

I would get another guide. The pushrod is only touching cause the rocker is to one side. I would pull the pushrod and give it a look over to be safe. (and to make sure it is straight.)

Edited 1 time(s). Last edited Sunday, January 29, 2012 8:59 PM

Freelancer1988 wrote:I would get another guide. The pushrod is only touching cause the rocker is to one side. I would pull the pushrod and give it a look over to be safe. (and to make sure it is straight.)

I'll get a new valve guide, but not just that one pushrod is hitting the cylinder head. I didn't look at all of them, but I know for sure more than just that one is like that.

Also, can anyone comment on if my procedure is correct for setting up the lash on these comp cam rockers? The stock process doesn't apply to these kinds of rockers. I figure I should just keep tightening until they aren't loose anymore. (and I shouldn't tighten any that are being opened by the cam at that part of the stroke cycle; they usually aren't loose anyways. )

I was too lazy to write it all out so I just googled it for you, and this is actually off Comps site.

HYDRAULIC LIFTER CAMSHAFTS

When the exhaust valve just begins to open on the #1 cylinder, adjust the #1 intake valve by loosening the adjusting nut slightly while spinning the pushrod until you feel lash in the rocker arm. Tighten the adjusting nut until the slack is taken out of the rocker arm and pushrod. Lightly turn the pushrod with your fingers as you tighten the adjusting nut, and you should feel a point where there is a little resistance. This is called zero lash – the point where you have taken all of the excess slack out of the pushrod. Turn the adjusting nut ½ turn past this point, giving you optimal pre-load for the rocker arm, pushrod and lifter. Follow this procedure by carefully adjusting each intake valve according to cylinder firing order.

Next, we’ll adjust the exhaust valves. To do so, you need to turn the engine over until the intake pushrod moves all the way up. Rotate just past maximum lift, where the intake will begin to close. The lifter is now at the base circle, and the exhaust valve can be adjusted. Note: DO NOT go too far down (over halfway) past the point of maximum lift. If you go too far, you will be in the overlap cycle – where intake valve lash is being taken up as the exhaust valve begins to open.

Rotate the exhaust pushrod with your fingers and begin to tighten the exhaust adjusting nut. When you begin to feel resistance against the pushrod, you are once again at zero lash. Tighten the adjusting nut another ½ turn. DO NOT OVERTIGHTEN. Repeat through the firing order until the lash on every exhaust valve has been set.

Now it’s time to double check, starting with cylinder #1. When the exhaust begins to open, check the intake. New hydraulic lifters shouldn’t be pumped up yet, so you should be able to spin the pushrod with some resistance. Think of the hydraulic lifter as a shock absorber – and you want to be right there in the middle of it. Until you have oil pressure, you’ll be able to push the lifter plunger into the bottom of the lifter. At that point, the lifter becomes solid. It might help to mark each rocker that has been set and then mark again each one that has been checked, giving the ones that are 100% finished a big “X” on the rocker arm body.

You would have liked my OHV build I had, not sure who on here bought it.

Thanks for the info JUCNBST, I vaguely remember this procedure, but It's such a pain to rotate the crank.... but I guess it's the best way.

I'll try this procedure when I find a new pushrod guide plate for the cracked one. On that topic of guide plates, does anyone know the GM part number? I've looked through the GM catalog

on gppartsdirect.com and also called my local napa, and other parts stores. So far, nothing. It seems like all these GM parts websites use the exact same catalog.