what abs plastic is on our cars??? i mean like what is it exactly on our cars that is abs??? i have a 98 cavalier btw lol...

All the hard plastic in the interior is ABS, think the airfilter box might be, the radiator cover maybe, but definitely all the hard interior plastic. Why do you ask?

Well i heard there is a way to make whats called "ABS SLUDGE" and all you do is mix shavings into acetone and it melts it into a sludge and you can use this stuff to bond plastics because all you do is spread it on your project and let it sit until the acetone evaporates and it rehardens into plastic i got this into from here:

http://www.mp3car.com/vbulletin/fabrication/45050-solvent-adhesives-why-don-t-more-people-use-them.html

Originally Posted by coachreed From the above link wrote:

Unfortunately, I didn't take pictures of the steps I've taken so far... can't find the ole digital camera! The steps are pretty easy to do by following directions though... as I mentioned previously, I used Acetone but the better chemical for this process is MEK (Methyl Ethyl Ketone)... unfortunately, my local Lowe's didn't have that so I went with Acetone.

To make the ABS paste, you need to mix ABS shavings or chunks in a condiment squirt bottle. I purchased my condiment bottles at Walmart in a three bottle set for about $1... came with one yellow, one red, and one clear (mustard, ketsup, and oil/vinegar I guess)... the type of pastic they are made of is stable with Acetone and MEK so all is good. The smaller your ABS shavings are the better but I didn't want to trash my garage or house, so I just broke some ABS into small chunks (1/4" x 1/4")... but for better/easier work on the mix, either use a drill to make shavings or run the ABS through a router... the router works the best. Now put your shavings into the condiment bottle... lots and lots of shavings... once you add a little solvent, the plastic will condense down quite a bit... you will most likely have to add shavings several times... once you have a decent amount (full bottle), make sure your cap is on tight and shake it up... there you have it... ABS paste...

As long as you have the bottle capped off good, the solvent can't evaporate out so it will remain as a paste... leave the cap off, the solvent evaporates and you then have a chunk of ABS...

The preparation of the plastics to be mated together is the most important part of the process. You MUST sand through all paints on the plastic so that you are working with exposed, virgin plastic. The solvents and paste will pretty much melt the plastic of your monitor housing and your dash panel to create one piece. If you still have paint on the plastic, you aren't doing anything worthwhile. The Acetone might penetrate the paint or finish but it could easy come apart later on. My suggestion is the be sure to sand down to bare plastic... no less!

If you've ever used PVC and PVC glue, you know how quickly this bond takes place. The thinner the paste is put on, the quicker it bonds. In the case of PVC pipe and couplings, you have a tight fit as it is... when you put the glue on the pieces and slip them together, they almost instantly stick. In the case of my dash, I poured the paste on pretty heavy so it is taking a little longer to set up... but rest assured, it will be solid soon. About half of my area that was glued was just a touch of glue... it is already hard as a rock... the other half, I poured the paste on about 1/2" thick so it takes longer to solidify... the thicker areas will also shrink up more as it hardens... but I expect to make one if not two more apps before done.

Has anyone heard of a place to purchase ABS in a two-part solution?

--------------------------------------------------------

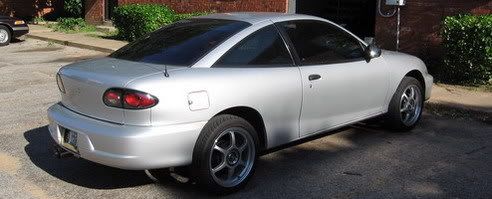

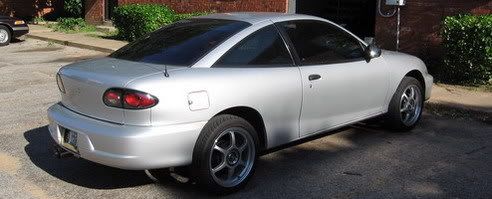

2002 Sunfire -->

- Ractive steering wheel

- ASA 17" EM9 + Nexen N5000 215/45/17 (steelies for winter)

- D-Spec Lowering kit @ 1.4" (issues currently

)

- Rockford P250.1 + MTX MZS1004 + Panasonic CQ-C8313U head unit

- Barely legal tint.