I've seen people post up about how they modified their eco valve covers in order to help their pcv system under boost but everyone just rinses out the shavings or hot tanking them. I've always thought that this wasn't enough. So I decided to open up my spare eco cover I planned on modding for my car in order to see what lays under the splash guard and modding mine accordingly. Depending where you place your A/N bungs you could be melting factory plastic baffles. I would suggest taking the entire valve cover apart and then modding your cover as you see fit. I hope this helps people down the road so they don't mess up covers in the process of modding them or possibly their engines if any metal shavings were to make it into the turbo inlet or blower.

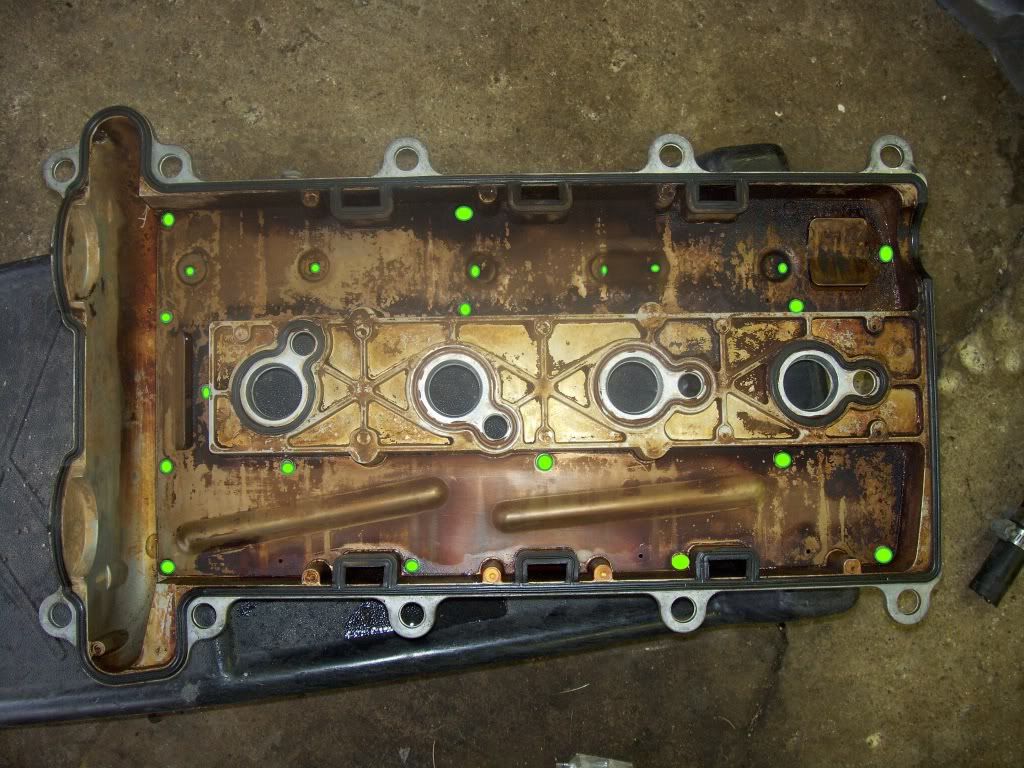

This first pic shows what needs to be drilled out in order to get the factory splash guard off. Every point is marked in green.

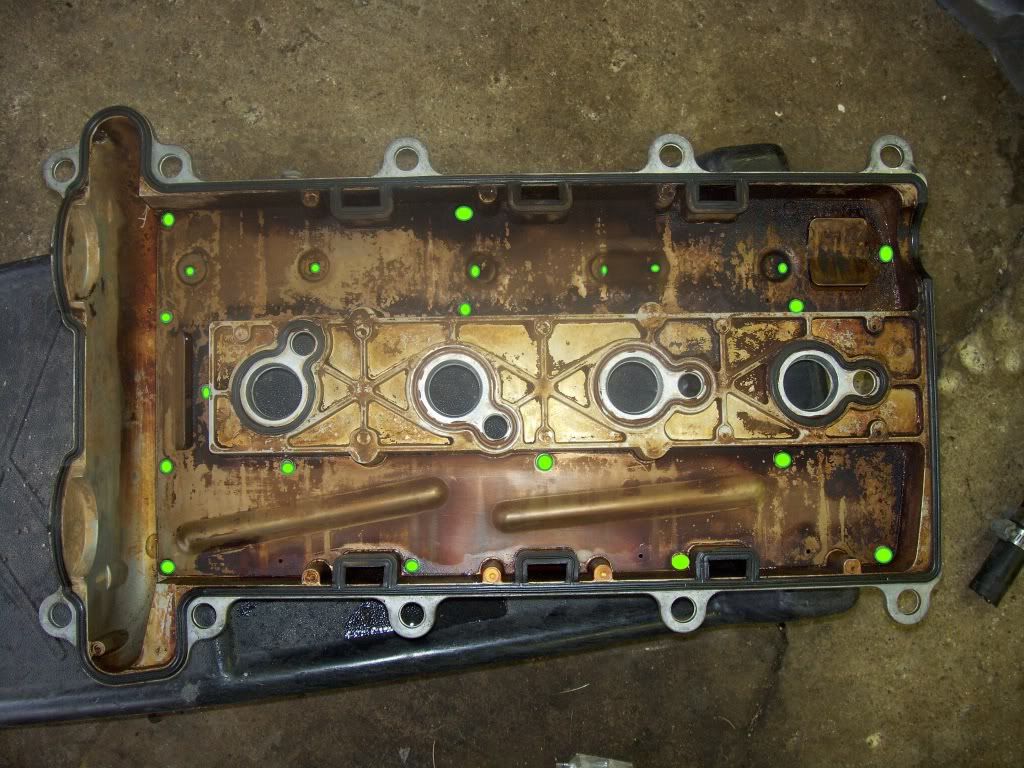

This next pic shows the underside once you pull the guard out. You'll notice gm has plastic baffling (marked with green squares) installed on the intake cam side of the motor but nothing on the exhaust side. The oil cap and factory pcv are marked in red.

This is showing an exploded view of how everything is laid out in the factory cover.

This shot allows a better view of the walls between the baffling

This is just a pic of a single plastic baffle inside the valve cover. It is made up of two halves that just snap together.

This shot is of the area under the factory plastic baffle in the middle of the cover. Notice that there is a little pocket and you can see where the discharge is on the factory channel for the pcv goes.

This is just a better pic of the exhaust cam side of the cover without the splash guard in place.

I hope this prevents any possible damage and helps some of you guys put together a better mod'd pcv system.

Happy Modding

Edited 1 time(s). Last edited Tuesday, January 31, 2012 2:26 PM

Very good info!

I've been meaning to pull apart a spare for a while now, but haven't gotten around to it yet. I knew there was baffling behind the guard, never knew it was plastic though.

Me too, I woke up early today and had nothing to do so I got off my ass and pulled it apart. I was surprised to see the plastic as well.

Yeah I knew they are plastic... problem is people getting their valve covers powder coated. Thats the problem. While powder coating it melts the baffles and distorts them and causes even more problems.

so where is the optimal place to drill for the modded PCV system?

I personally will be adding two ports on the intake cam side, as under hard acceleration oil will naturally go toward the exhaust side. But thats just me.

can u post a picture that will show where you will be adding the ports at?

EvoFire wrote:can u post a picture that will show where you will be adding the ports at?

I haven't planned that out 100% yet as I just now learned where baffles, and pcv vents go. Once I get to the point where I sneek this into school to tig the A/N fittings on I'll post up again.

Nice, thanks for posting this Jucnbst!

Good stuff, how do you plan on getting the guard back on?

1994 Saturn SL2 Home Coming Edition: backup car

2002 Chevy Cavalier LS Sport Coupe: In a Junk Yard

1995 Mazda Miata R-package Class=STR

Sponsored by:

Kronos Performance

WPI Class of '12 Mechanical Engineering

WPI SAE Risk and Sustainability Management Officer

^^Exactly what I was thinking / waiting to see

I plan on using one of the tig welders at school to plug weld the holes.

Thats what I assumed. Do you think there's enough meat there to drill and tap for some short screws though?

1994 Saturn SL2 Home Coming Edition: backup car

2002 Chevy Cavalier LS Sport Coupe: In a Junk Yard

1995 Mazda Miata R-package Class=STR

Sponsored by:

Kronos Performance

WPI Class of '12 Mechanical Engineering

WPI SAE Risk and Sustainability Management Officer

You could drill and tap maybe a few but majority would need plug welds. Even then if you didnt drill it just right I'd bet that it would ruin the post and then couldn't plug weld that spot without some work.

Philly D- That would work, but personally for higher hp cars I'd still feel better adding two -12 or bigger AN fittings . My personal thinking is that having smaller sizes like -8 or -10 would have a higher chance of picking up oil droplets better due to the higher velocity if not properly baffled as opposed to a much larger an fitting where velocity would be lower but the volume of air would be greater. Thats my thinking on it but I'm not an engineer. Think of drinking your pepsi with a tiny straw as opposed to a bigger straw. With one little straw the pop shoots up the straw faster than the bigger diameter one and when you add a second straw it makes it even slower to get to the top of the straw for you to drink but you get more pepsi. Does that make sense to you?

Im thinking im going to add the ZZP oil cap to mine. I have one catch can and im thinking that plus the breather filter will help a lot with mine.

JUCNBST wrote:Think of drinking your pepsi with a tiny straw as opposed to a bigger straw. With one little straw the pop shoots up the straw faster than the bigger diameter one and when you add a second straw it makes it even slower to get to the top of the straw for you to drink but you get more pepsi. Does that make sense to you?

I'm now thirsty and want a Pepsi, damn you.

this is the start of my signature: have you read the

RULES yet?

my carDomain updated 6/11/10 Forged and Supercharged

A little off topic, but any suggestions on powder coating as to avoid damaging the baffles? Would you suggest pulling apart the cover before powder coating or just deal with the melting baffles?

Honestly no offense but think about what you just said....you answered your own question. Why not paint it?.

JUCNBST with the straw idea, think of the same example but with four straws to one source, the suction will be much less per port.

Thats true cinny but how many of a smaller size would you need to equal the volume of 2 big ones to one source? Plus an fittings add up quick cach wise.

what I did was add 3 more to the top of the cover and keeping the stock port, they are all the same size. (I think 5/16 of the top of my head) TIGing in isn't an option for me right now, I don't have the tools, and shops are few and far between where I am now (I sure miss FT. Lauderdale) I drilled and tapped with brass fittings, and they will all feed into one vacuum block.