The plan is to take a Vortech V-9 G trim supercharger (the one used by RSM/Z-spec) and run it off the accessory belt. We all know that the RSM kits make 6-7 PSI. According to Vortech this s/c is capable of making 20 PSI @ 800 CFM. The problem with RSM's setup is that the s/c is driven off the intake cam which spins at half the speed of the engine. The solution, rip out the A/C on my 2.4L Twin Cam and mount the monster there so it can be run off the accessory belt.

I've been working on this project off and on for a few months. I don't get as much time to work on it as I'd like so its been rather slow. I had planned on waiting until it was nearly complete to post anything but I figured what the heck...

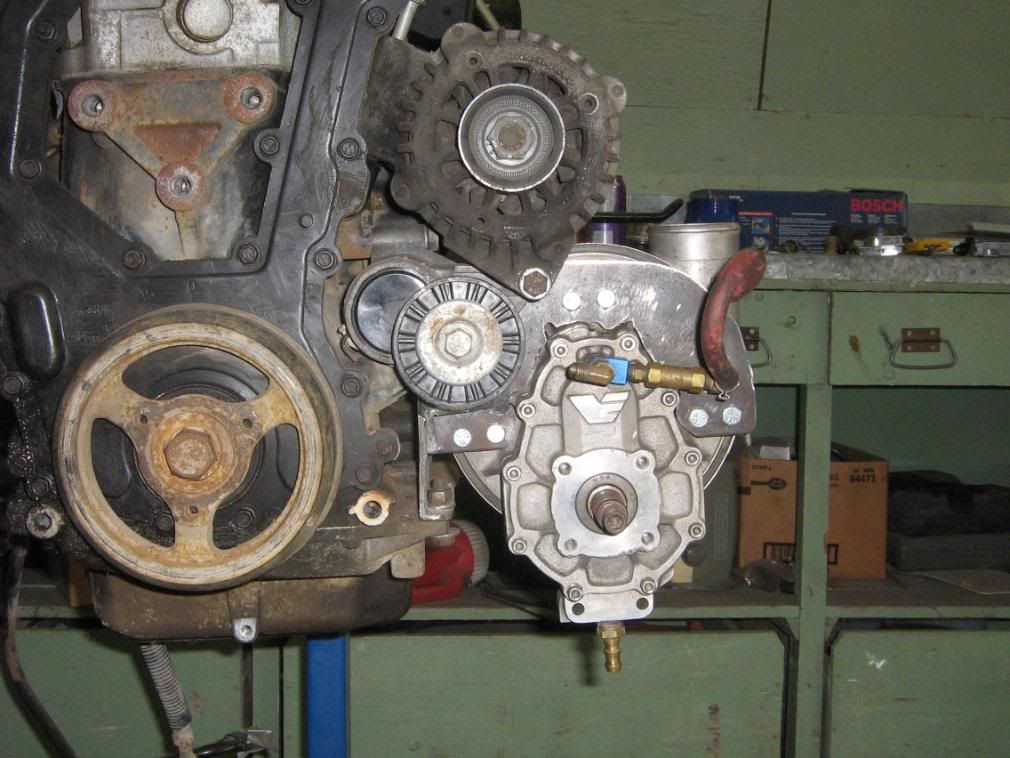

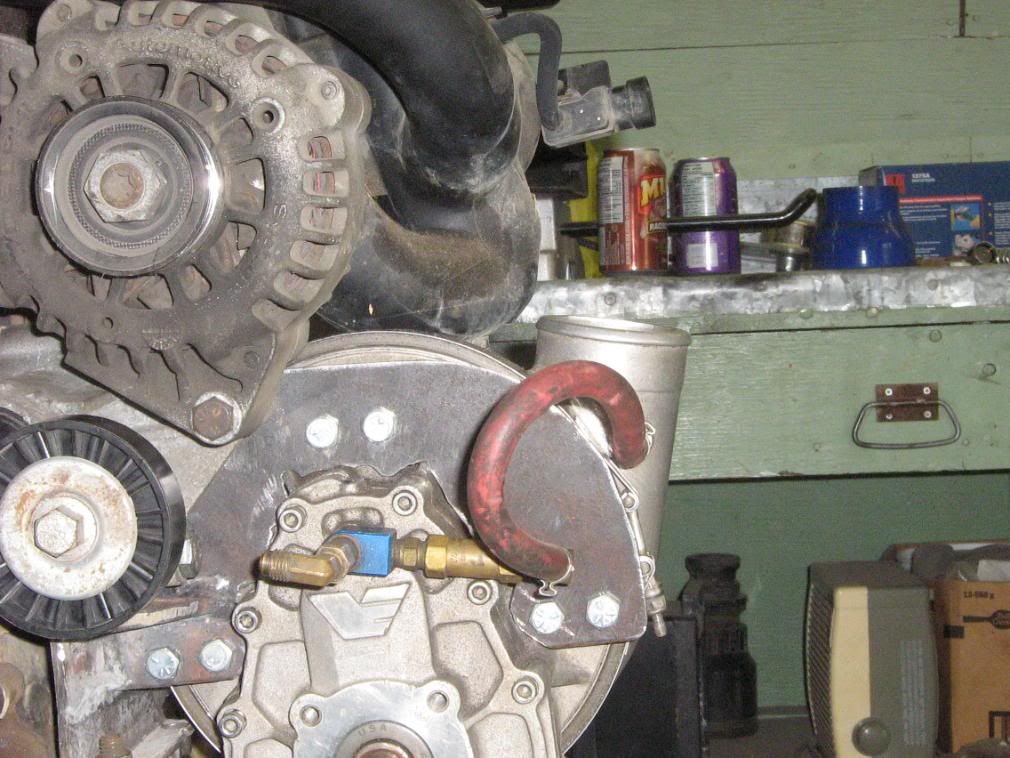

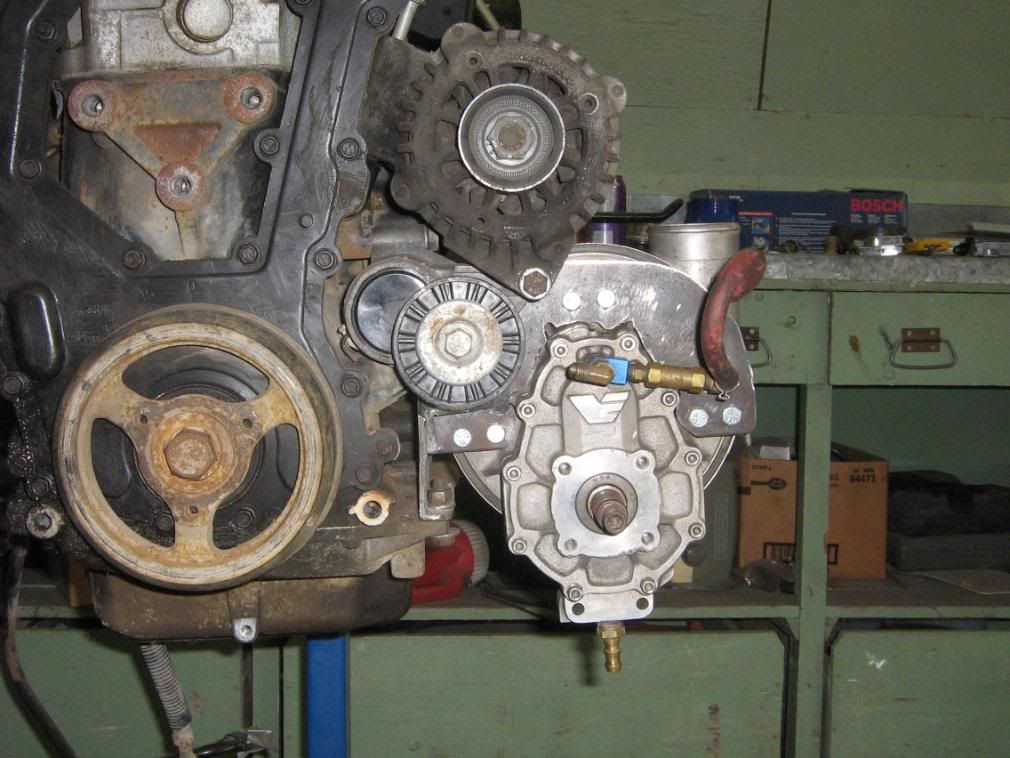

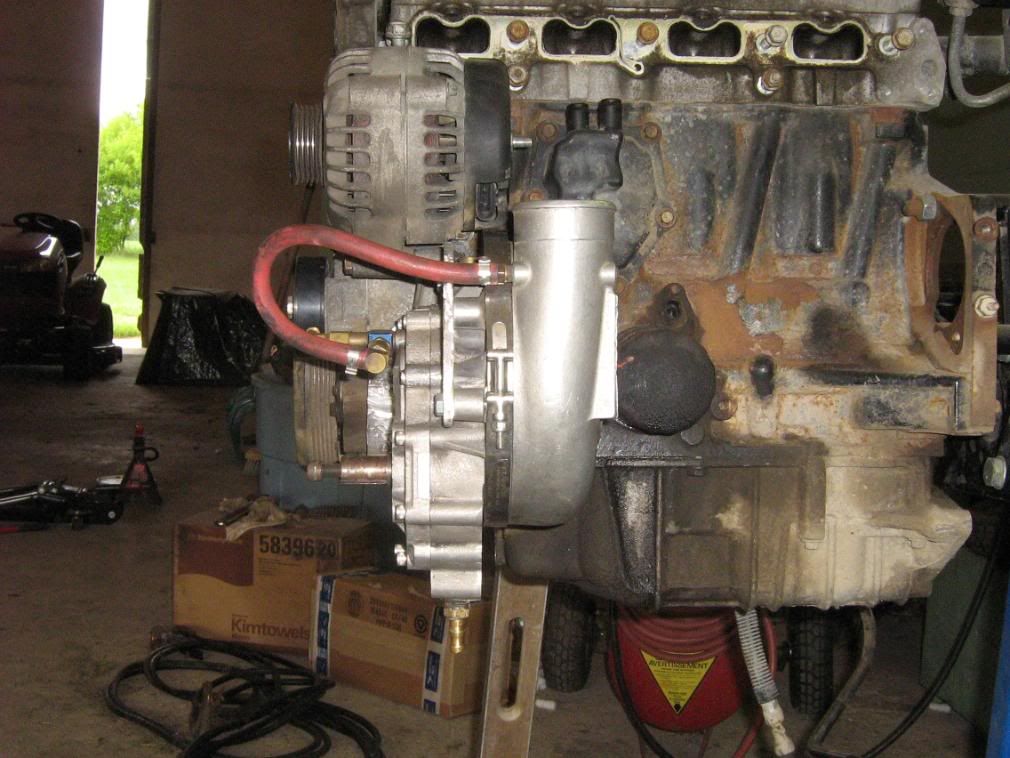

Mounting Bracket... Keep in mind that this will need to be taken to a machinist to be milled square. I think its very close but I'd rather be sure. I also just finished building it when the pics where taken so it still needs some cleaning up.

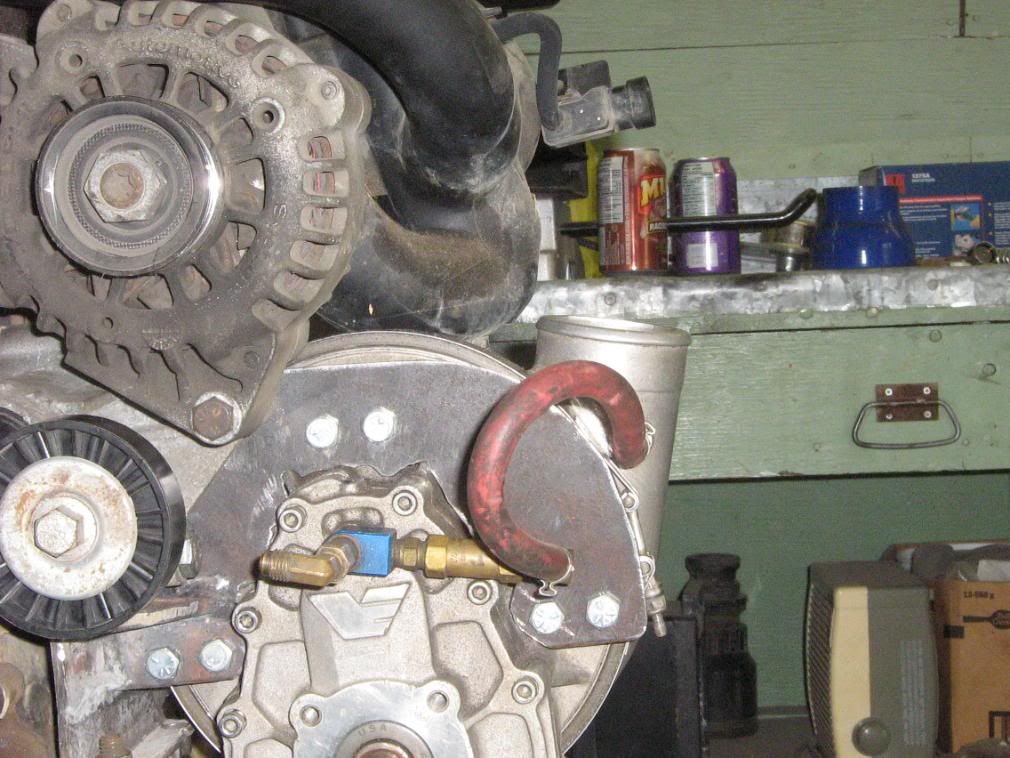

I also had to modify the belt tensioner to make a little more room.

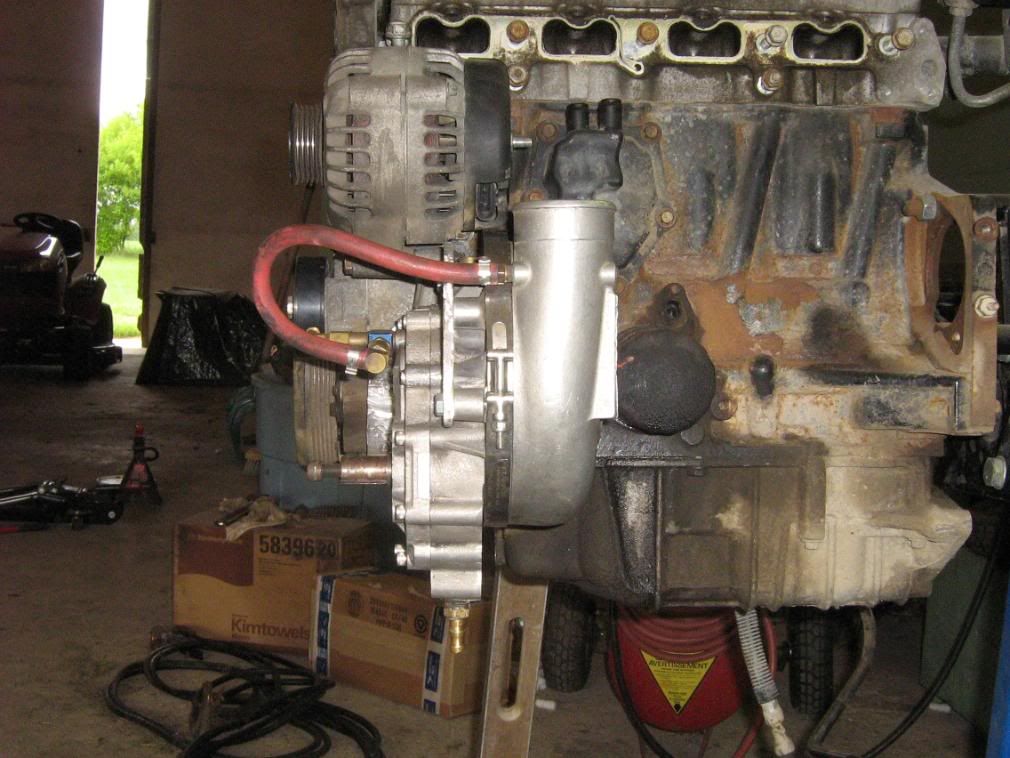

Mounting bracket on my mock up engine with the s/c installed.

Threw the intake manifold onto check for clearance. This wasn't a big issue since i have a 2.3 HO manifold I was going to use if the stock one wouldn't fit.

All C&C welcome

Edited 1 time(s). Last edited Sunday, June 22, 2008 5:41 PM

Nice work. Are you planning to intercooler it?

FU Tuning

FU Tuning

I'm not going to intercool yet. For now I'm going to stick with 7 PSI or so. Once i get the time and money to do an engine build on my spare engine i'll intercool and up the boost

Awesome stuff man, should be a fantastic

.

My Cav

My Cav

I give up...

i'm buying a VW those people love trees, so they should love eachother too... "Andy"

Looks like a great project. I have been hoping someone would wind one of these blowers up. I hope you travel past your initial 7lb goals.

One thing I might worry about is the ability for the blower to drain it's oil well. I believe turbo's suffer the same issues when mounted low.

Craig Lewis wrote: One thing I might worry about is the ability for the blower to drain it's oil well. I believe turbo's suffer the same issues when mounted low.

I have thought about this and i plan on putting an in-line pump (something like what they put in for remote mount turbo systems) in to help drain the oil.

I had this same idea for the 2200 awhile back as I had no A/C as well and all that space. One way I thought of to help with the low mounting is to use a small procharger supercharger I can't recall which model of the top of my head. But the plus is there internally oiled no pan tapping and no extra wiring on your part for an inline pump. I thought I would post this as food for thought.

Good work, its nice to see your giving this thing a chance, it should produce good boost right off the acc. belt.

"Go Before Show Yo."

CARCUSTOMS.NET, THE BEST SERVICE ON THE ORG!!!

I have a feeling your going to run into gearing issues with that. Even if you got a pulley on there just as big as the crank pulley your going to run it 2 times as fast as RSM had it running. Not say RSM knew anything im just saying that as fact. If that was already getting you 7psi @ say 6000rpm your looking at the same boost waaaaay earlier. You might see if you can get a new set of gears from vortech to pop in there and slow it down. I think you might need to. As you got it now I'd say your definitely going to boost higher than you will want too.

Other than that.....looks good man keep it up.

Edited 1 time(s). Last edited Monday, June 23, 2008 7:50 AM

extremely cool. oil filter re-location kit FTW

looking forward to progress on this for sure.

Joshua Dearman wrote:I have a feeling your going to run into gearing issues with that. Even if you got a pulley on there just as big as the crank pulley your going to run it 2 times as fast as RSM had it running. Not say RSM knew anything im just saying that as fact. If that was already getting you 7psi @ say 6000rpm your looking at the same boost waaaaay earlier. You might see if you can get a new set of gears from vortech to pop in there and slow it down. I think you might need to. As you got it now I'd say your definitely going to boost higher than you will want too.

Other than that.....looks good man keep it up.

I'm going to have to get a custom pulley made up for it any way since the shaft on the s/c is about 2 inches from the belt path. I crunched some numbers when i first started the project to find out what size of pulley i need to get the same RPM as the RSM kit had. If i dig around a bit here i might find the paper that i did all the math on. I think i need a 3.5 or 4 inch pulley if i remember right.

Im really excited to see what this supercharger can really do. Good work man.

Very sweet.

~2014 New Z under the knife, same heart different body~

______________________

WHITECAVY no more

2012 numbers - 4SPD AUTOMATIC!!

328 HP

306 TQ

sleepy sunfire wrote:Joshua Dearman wrote:I have a feeling your going to run into gearing issues with that. Even if you got a pulley on there just as big as the crank pulley your going to run it 2 times as fast as RSM had it running. Not say RSM knew anything im just saying that as fact. If that was already getting you 7psi @ say 6000rpm your looking at the same boost waaaaay earlier. You might see if you can get a new set of gears from vortech to pop in there and slow it down. I think you might need to. As you got it now I'd say your definitely going to boost higher than you will want too.

Other than that.....looks good man keep it up.

I'm going to have to get a custom pulley made up for it any way since the shaft on the s/c is about 2 inches from the belt path. I crunched some numbers when i first started the project to find out what size of pulley i need to get the same RPM as the RSM kit had. If i dig around a bit here i might find the paper that i did all the math on. I think i need a 3.5 or 4 inch pulley if i remember right.

I dont mean to come off rude but what numbers are there to crunch really? To be "2X" the original speed the pulley needs to be the EXACT same size as the crank, whatever size you put on that. I'd say your looking at like a 8-10" pulley or so to get back to the exact same speed as what it was turning when connected to your PS. I'm just trying to help....EDIT: Unless im the one out in left field....which I could be....im forgetting that there was a geared hub that ran off the PS and increased the rpm supplied to the charger right?

Edited 2 time(s). Last edited Tuesday, June 24, 2008 9:05 AM

I love this idea! I have been waiting for a Centrifugal charged J for a long time! Running off the cam is a waist of time, it should be ran off the accessory belt. Here are the specs on the v9

"A compact supercharger designed for high flow in a compact package.

* Straight cut spur gear

* Fits engines up to 575 horsepower

* Maximum airflow: 800 CFM *

* Maximum boost pressure: 20 PSI *

* Absolute maximum impeller speed: 65,000 RPM

* Adiabatic efficiency: 72% **

* Available with straight discharge in clockwise or counterclockwise rotation"

This charger will be killer. Josh Dearman, running a pulley that big would barely allow for boost to be made, if any at all. Running straight off the crank or accessory belt is best. You see running off the cam would mean only half of what can be made is used. if the Engine is turning 4000RPM that means the cam is spinning 2000RPM. If the chargers ratio is 4.65:1 and the engine is turning 4000 RPM then the charger is turning 18,600 with the same size pulley and only 9,300 RPM off of the cam. Now reducing pulley size allows the charger to be spun to where it can make boost. Becuase the charger is spinning does not mean it is in boost. I don't feel up to mathematics right now, but its a simple equation as to have the right pulley size.

jd soza wrote: Josh Dearman, running a pulley that big would barely allow for boost to be made, if any at all. Running straight off the crank or accessory belt is best. You see running off the cam would mean only half of what can be made is used. if the Engine is turning 4000RPM that means the cam is spinning 2000RPM. If the chargers ratio is 4.65:1 and the engine is turning 4000 RPM then the charger is turning 18,600 with the same size pulley and only 9,300 RPM off of the cam. Now reducing pulley size allows the charger to be spun to where it can make boost. Becuase the charger is spinning does not mean it is in boost. I don't feel up to mathematics right now, but its a simple equation as to have the right pulley size.

^umm....you do know that RSM sold kits that PTO'd off the cam and made 8psi of boost right?.....so dont think that was my idea or say that it wouldn't work.

The math is very simple, we can all do it. What I was trying to say if you ACTUALLY READ IT was if the charger was making 7-8psi off the cam (1/2 engine speed) and you throw a 4" pulley on it with a 6" pulley on the crank you'll be more than double the speed right there. When the IP is trying to keep stock internal boost pressures like the original 7psi which isn't going to work. Now the only thing that could save it is if there was a geared PTO off the cam instead of a direct drive that increased the speed of the charger(which is what I dont know, but anybody who bought the kit would), then you could do that math and possibly get the same speed out of it with a reasonable sized pulley running off the acc belt.

Edited 1 time(s). Last edited Tuesday, June 24, 2008 11:45 AM

Very very interesting... I'll be watching this. Personally I would run the outlet upside down and intercool it right away... but that's me.

Oil pump on the return is definitely a good idea... if you can manage it, put it back into the block and not the pan.

Good luck with the custom pulley... seems like a bit of math to get it setup right.

-Chris-

-Sweetness-

-Turbocharged-

Slowly but surely may some day win this race...

Wow,looks good man.Thats the way the vortech shoulda been used in the first place.Sometimes i miss the vortech blower on my z.. I sold the kit when i was getting the cobalt.Besides the oil leaks,the 1st blower seizing up on me,the second one leaking oil internally,and the broken cam shaft,it wasnt a bad kit,lol.

Peter

'06 Cobalt ss/sc W/G85 Package

Gm Stage II W/2.79" Pulley

K&N Drop In Filter

Custom Magnaflow Dual Exhaust

Josh: Your not coming off rude. I appreciate the fact that your concerned about a potential problem. I'll throw some more info in on the pulley setup since I'm not sure how much you know about the RSM kit . I was a belt driven deal with a 6 or so inch pulley on the cam and a 1'' pulley on the s/c. So it was "geared up" a bit. here's some pics from when i first got the kit, you can see the small pulley on the s/c and the larger cam pulley sitting beside the injectors.

Heres a

.PDF file for anyone looking for specs. Its the V-9 G trim (Last on the chart)

So using the info in the specs:

Max efficient impeller speed - 60,000

gear ratio - 3.45 : 1

Crank pulley - 8" (approx)

Max engine RPM - lets say 7000

60,000 / 3.45 / 7000 = a 2.48 : 1 gear ratio needed between crank and s/c pulleys

8 / 2.48 = 3.2" s/c pulley to reach max efficient impeller speed @ 7000 RPM

please correct my math if I'm way out in left field here

Keep in mind that I'm not planning on using that much boost to begin with so it'll be bigger than 3.2" when i get it made.

Edited 1 time(s). Last edited Tuesday, June 24, 2008 5:52 PM

This looks pretty promising. I do agree with sweetness tho, clock the output and intercool it straight from the beginning.

Thats sweet looking man. What are you going to be using for engine management? Do you have HPT or are you going the stand alone route? I talked to a guy at AEM on the phone, he told me to buy a honda box and get the pigtails to make it a universal. This looks promising as the fact that it controls everything and can be had for a decent amount of money. I think I have a new project rolling my way. LOL

I was kind of holding out for Shifted's project to get finished up but it looks like that could be a bit more of a wait than expected so I'm looking at HPT.

Time for an update.... I told you progress would be slow

Not a huge amount has happened but i have a little stack of parts for the project.

HP Tuners PRO

Ford green top injectors

Club Coachman intercooler

Oil filter relocation kit

Supercharger is in the process of getting some fresh bearings and seals. I had one wrong bearing sent to me so i had to wait a week or 2 to get the right one shipped to me. i just have to put it all back together.

SO as you can see i decided to intercool right away.

Things still need for the build:

Injector clips (junkyard will supply those)

Scavenge pump to pump the oil from the S/C back into the engine

Intercooler piping

Various small hoses and fittings for the S/C oiling system

Most of the parts will be going in next weekend

EDIT: When i mean most of the parts i mean te injectors and HPT. The S/C is waiting on the custom pulley i'm getting made up at the machine shop.

Edited 1 time(s). Last edited Thursday, August 07, 2008 6:24 PM