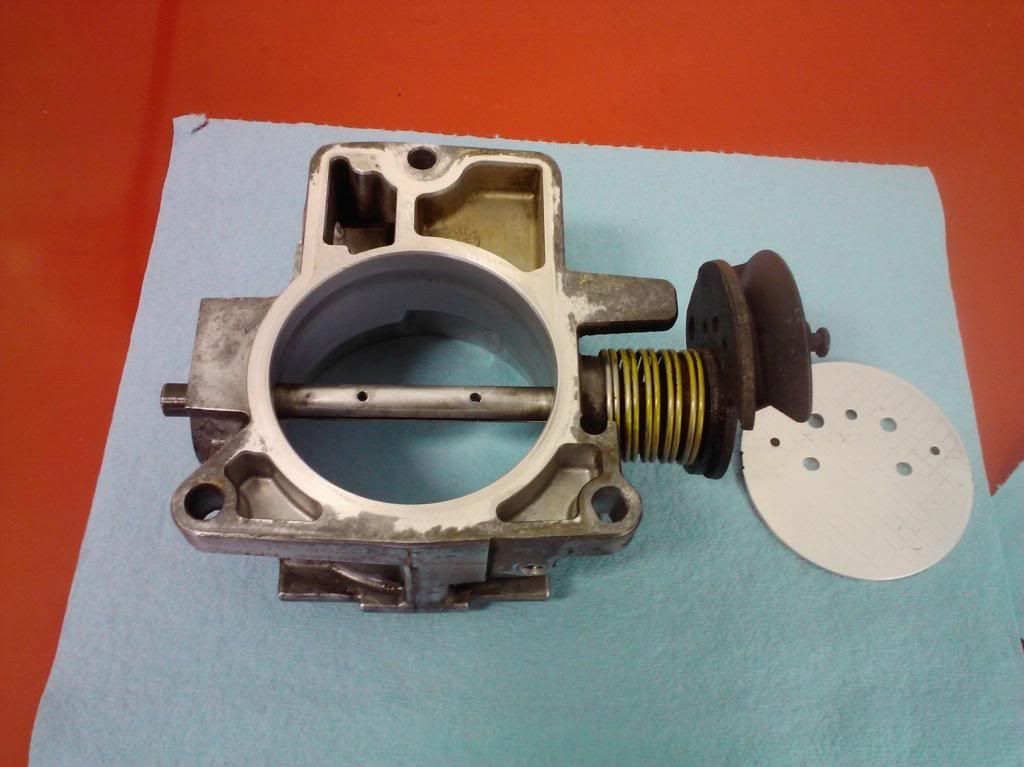

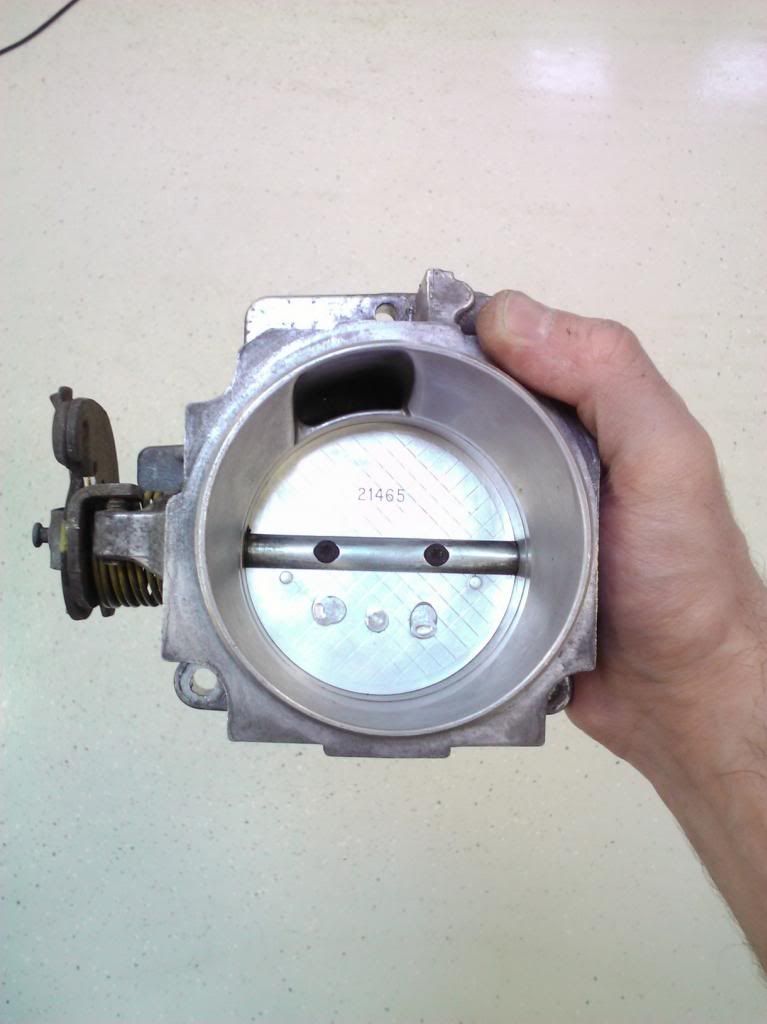

Thrice . wrote:Dunno why GM put that stupid little restrictor in there, but it's coming out while I'm cleaning it.

My guess would be because it was probably easy to burn rubber in a 5.7 truck pulling out from a light. That probably helped people pull out smoother.

Keep up the good work sir

"In Oldskool we trust"

Dam that was one caked tb. Looks good now.

Didn't get much time to work on the car, but what time i did have was pretty much dedicated to reading my Haynes manual thoroughly on reassembly. Next chance i get to work on the engine, should be much faster assembling everything.

GM trq specs for the main bearing caps are 15FtLbs.....wtf? ARP says 80FtLbs with their molylube and studs sooooo....

I'm getting tired of helping my buddy with his dads house, and not working on my build. Getting close to telling him i'm done lol.

I looked up the ARP recommend torque....ARP indeed says 80ft/lbs with their molylube.

I honestly do not recall what mine are torqued to.

PRND321 Till I DIE

Old Motor: 160whp & 152ft/lbs, 1/4 Mile 15.4 @88.2

M45 + LD9 + 4T40-E, GO GO GO

Hmmm looks slow

RIP Cpl Derek Kerns And Cpl Robby Reyes

24th MEU VMM-261 (REIN) V22 Crewchiefs

11 April 2012 Morocco (African Lion)

MillerBilt Racing wrote:Hmmm looks slow

Haha i know eh.

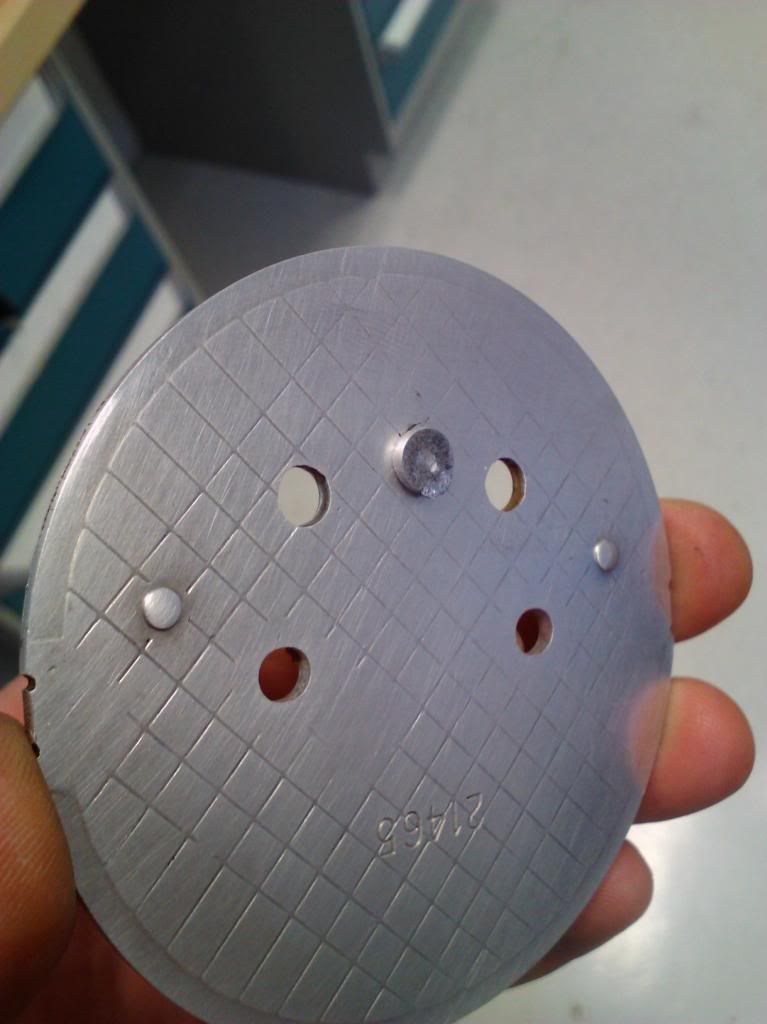

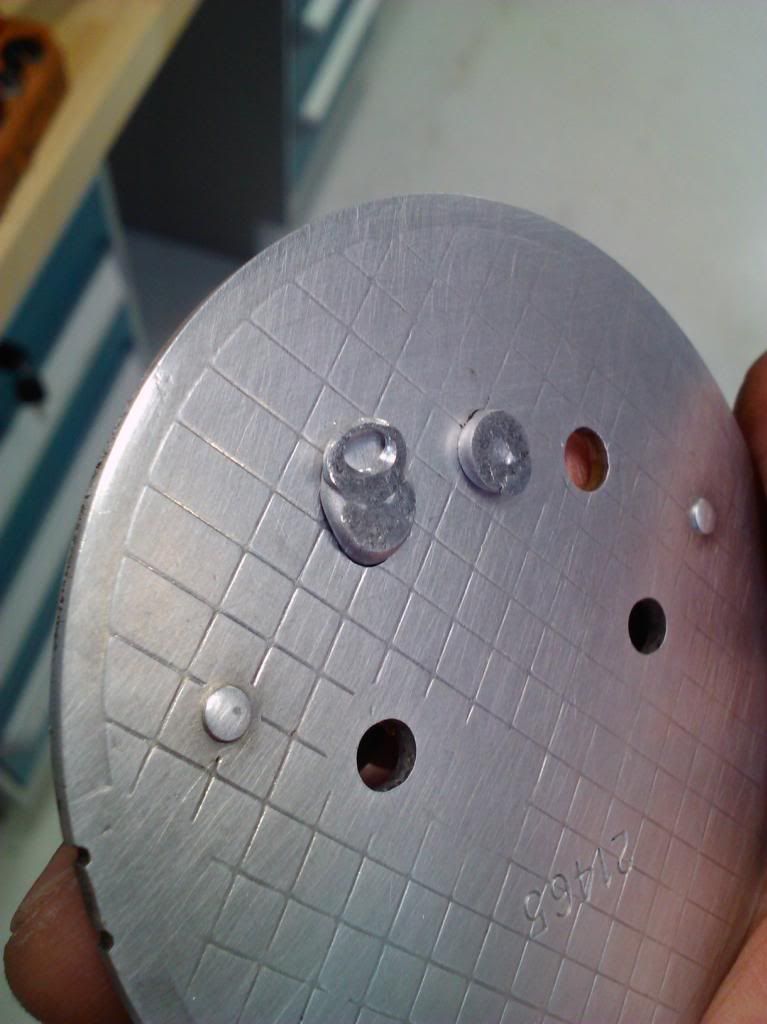

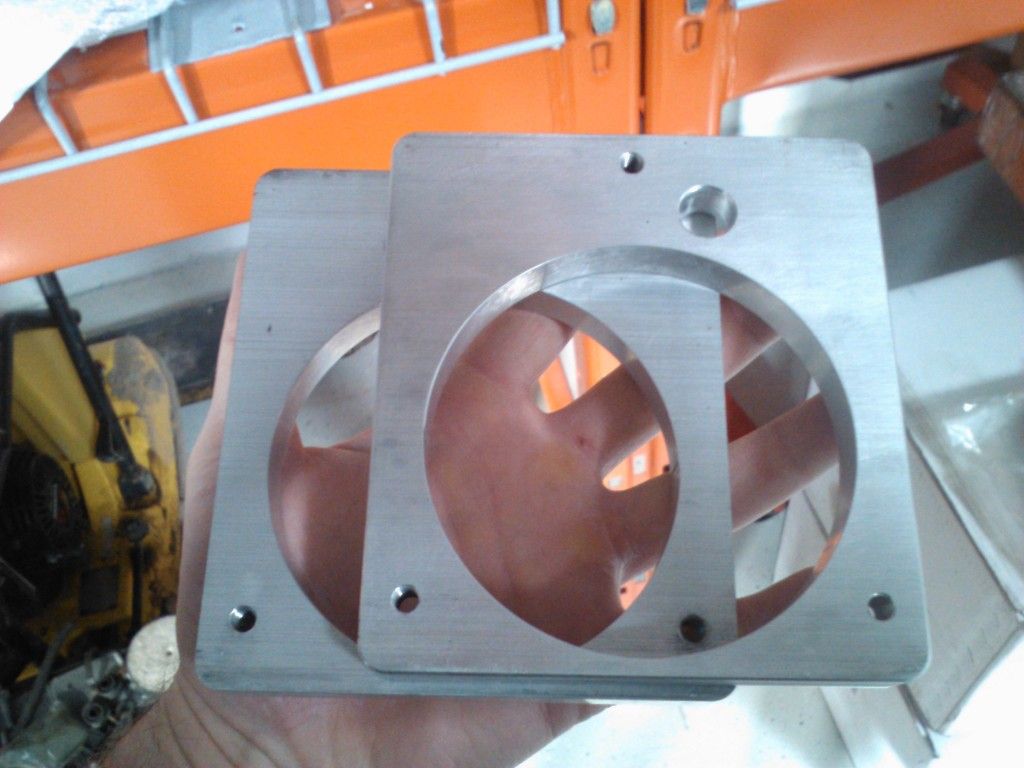

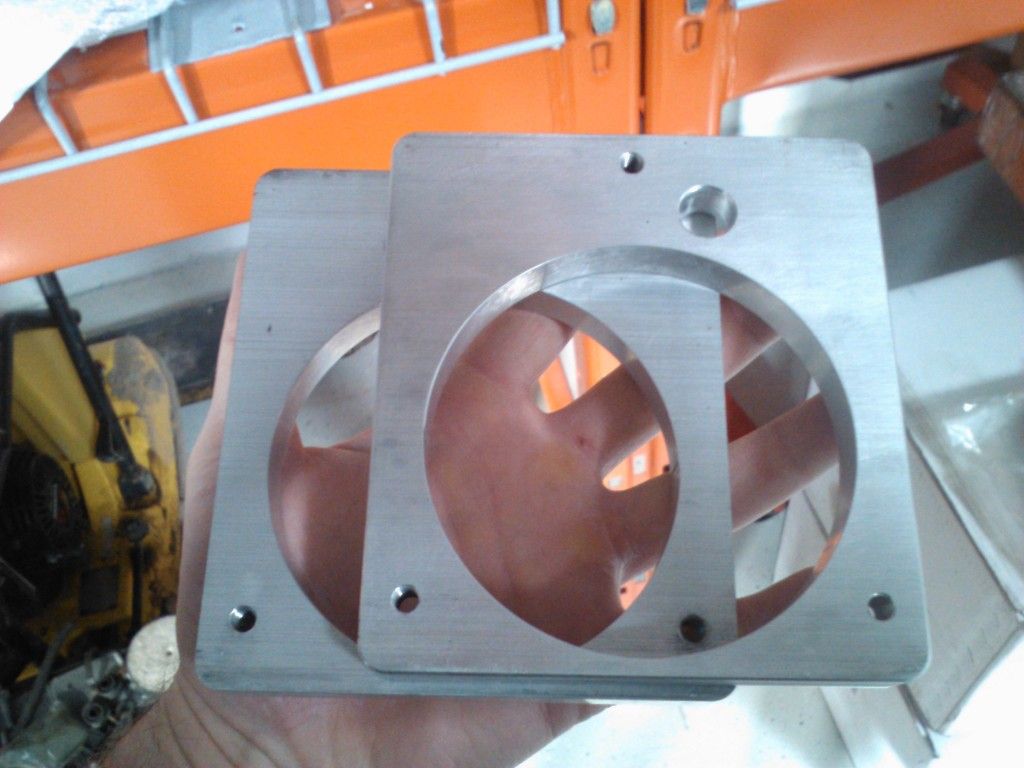

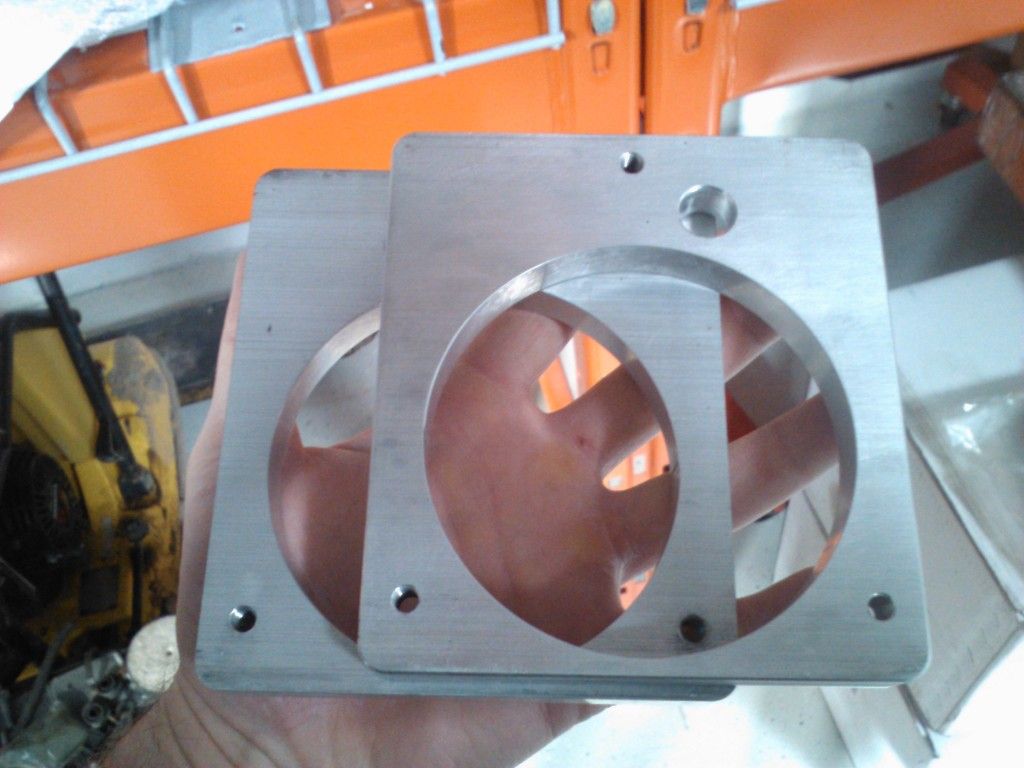

So i got in my flange(s) for the intake. Figured i'd buy 2 just in case i'm incompetent

Then i realized the company i bought them from screwed up their process.

They managed to make the bore 92mm instead of 75mm

So minor setback (again) but it will all be figured out in a week or so. I contacted the company i bought them from (theboostdepot.com) and it's being rectified free of charge.

I haven't been in town for a couple weeks because i was exhibiting in Calgary at the Global Petroleum Show in the BMO Centre, but when i got back i was having some withdrawal and found a spare hour to touch some engine

At this pace i should be done by sometime mid 2027 lol.

Thrice . wrote:MillerBilt Racing wrote:Hmmm looks slow

Haha i know eh.

So i got in my flange(s) for the intake. Figured i'd buy 2 just in case i'm incompetent

Then i realized the company i bought them from screwed up their process.

They managed to make the bore 92mm instead of 75mm

So minor setback (again) but it will all be figured out in a week or so. I contacted the company i bought them from (theboostdepot.com) and it's being rectified free of charge.

I could use an adapter like that

Jason

99 Z24

LG0/LD9 for Life

10 Year Bash Veteren

I'm pretty sure those are for alignment and you would be ok, but do not go just on what I say.

FU Tuning

FU Tuning

This is going to get REAL interesting fitting this fuker in the engine bay....

Unfortunately my plan to clock the compressor housing downward won't work without a spacer on the T3 flange moving the turbo down some, because the housing hits the header. I didn't account for this turbo being THAT much larger then the S200SX i was originally planning on using.

Good thing is this is only mock up for now. The engine will be broken in NA, keeping it as close to stock as possible (including stock injectors and tune) in hopes that will aid in me passing emissions.

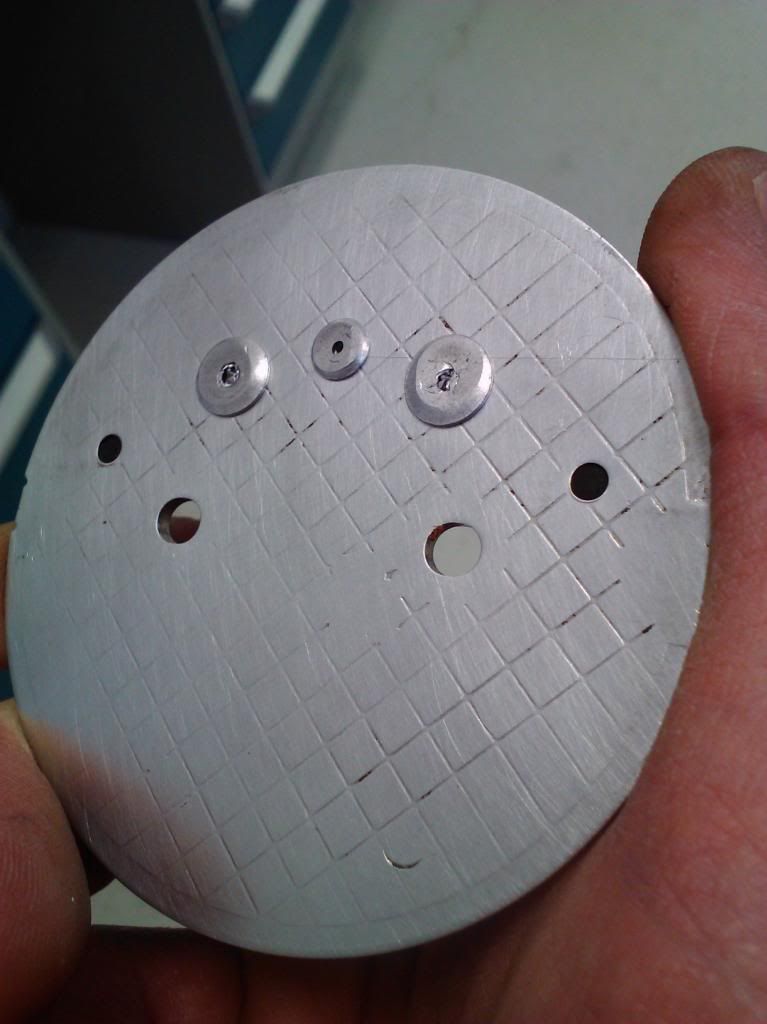

Made some alignment sleeves for the block/head. I had some running around to do today so i didn't get much else accomplished sadly.

Next weekends list of STD's (Sh1t.To.Do.) includes:

-Drill hole in oil pan/weld -10 AN fitting for turbo drain.

-Either machine or buy a T3 flange spacer, as well as mounting studs/nuts for the turbo.

-Spray headgasket with copper spray, mount the head, and finally torque the son of a bitch down.

-Start final assembly with gaskets and stuffs.

I'll leave it at that for now so it's at least something attainable.

Side note, Karo's head stud kit didn't come with torque specs for the nuts. Anyone know them for the LD9?

turbo...and firewall.....good luck man.

ALSO< SWEET AS HELL LOOKING.

Edited 1 time(s). Last edited Sunday, August 10, 2014 5:54 PM

PRND321 Till I DIE

Old Motor: 160whp & 152ft/lbs, 1/4 Mile 15.4 @88.2

M45 + LD9 + 4T40-E, GO GO GO

since it wont fit just sell it back to me

RIP Cpl Derek Kerns And Cpl Robby Reyes

24th MEU VMM-261 (REIN) V22 Crewchiefs

11 April 2012 Morocco (African Lion)

That setup looks awesome. Gotta love the BW turbos.

Thrice . wrote:Made some alignment sleeves for the block/head. I had some running around to do today so i didn't get much else accomplished sadly.

Next weekends list of STD's (Sh1t.To.Do.) includes:

-Drill hole in oil pan/weld -10 AN fitting for turbo drain.

-Either machine or buy a T3 flange spacer, as well as mounting studs/nuts for the turbo.

-Spray headgasket with copper spray, mount the head, and finally torque the son of a bitch down.

-Start final assembly with gaskets and stuffs.

I'll leave it at that for now so it's at least something attainable.

Side note, Karo's head stud kit didn't come with torque specs for the nuts. Anyone know them for the LD9?

My block does not have the sleeves either because of the 1/2 head studs. I have been told I shouldn't have a problem

Jason

99 Z24

LG0/LD9 for Life

10 Year Bash Veteren

Lol I'm glad I'm not the only one who went "oh man that turbo is a lot bigger than the mock up"

This looks awesome I'm happy to see it finally coming together!!

"A car just isn't a car without a little blood, sweat, and beers." -- Shadowfire