yes, due dates suck.

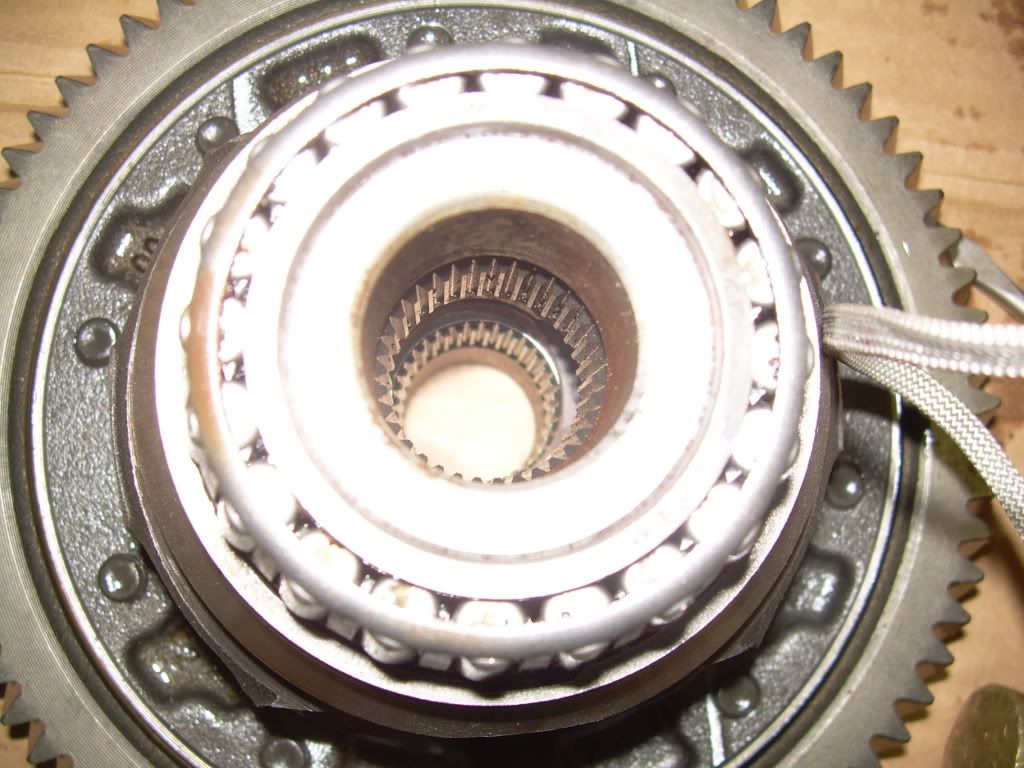

damn dood, make sure you media blast that nasty trans case

All I want... is a little of the good life

Anyone have any idea if i'm to use any type of sealent when bolting the tranny back together? I was thinking RTV, but i'mnot sure if i'm to use anything to aid in sealing.

I would for sure use some kiond of sealant on the tranny. The GM gray sealant works great.

FU Tuning

FU Tuning

*update*

All exhaust stuff has been ordered and the bumper support has been finished being cut as well as the crush guard being trimmed. Nothing worth taking pictures over, really.

Heard back from Karo about the pistons, I'll ordering them in 1-2 weeks. I decided to hold off because his hookup at Wiseco is in the hospital, so i give him a bit to get back on his feet.

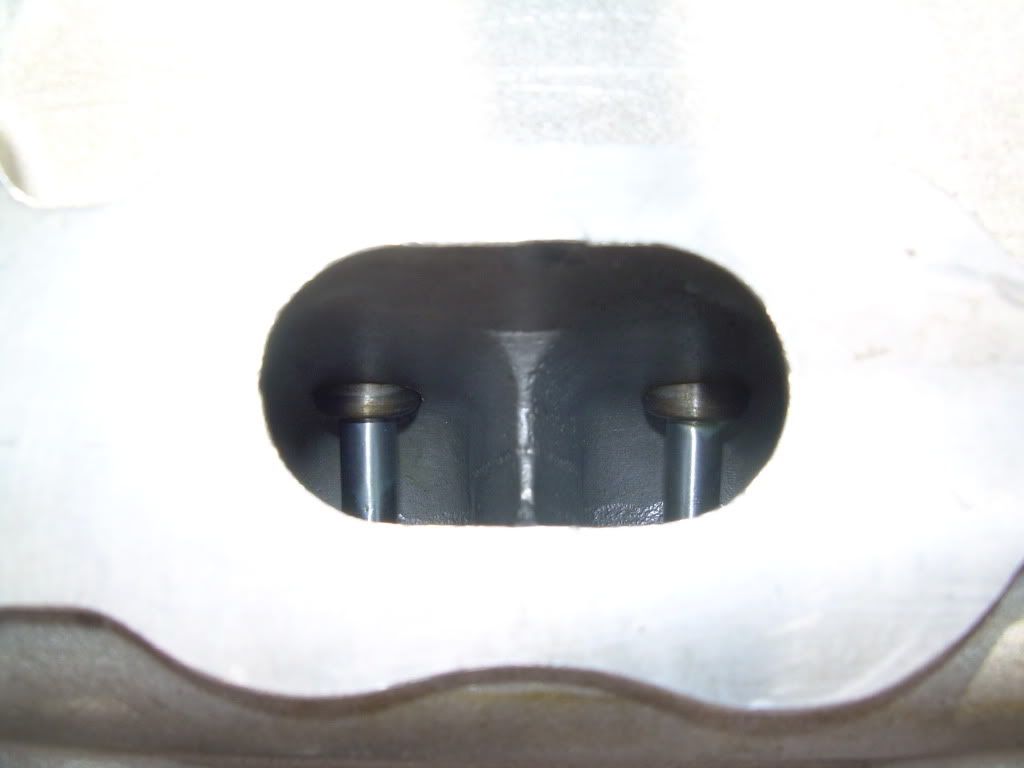

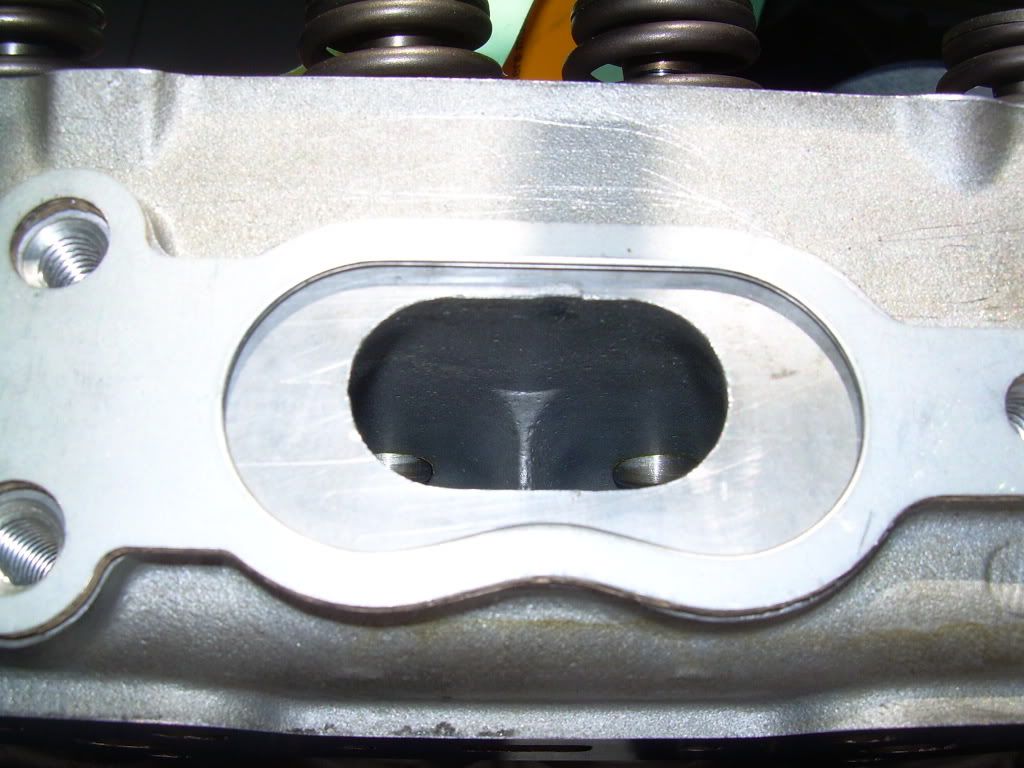

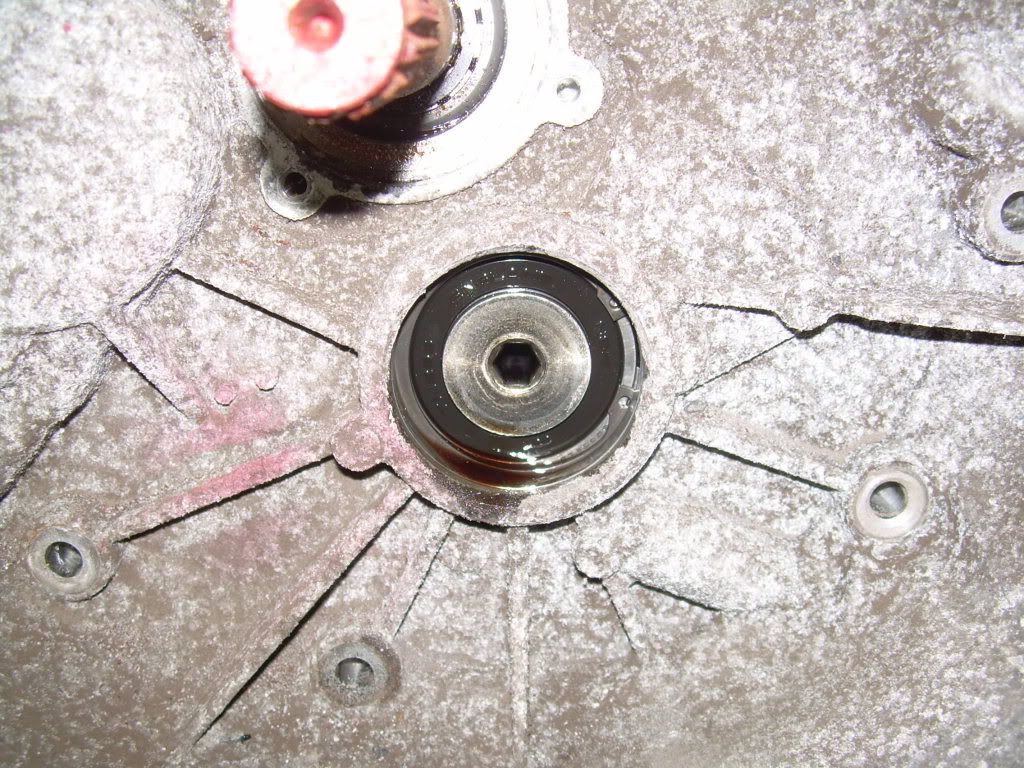

Thrice . wrote:Ok, pictures of the head, and what i used to reverse bleed the clutch system.

For reverse bleeding the clutch, it's just a simple mini oiling can that i bought from Part Source (Auto Zone) and the hose i believe is 1/8th or 3/16th. I can't quite remember, sorry. The person at Part Source should be able to just match up the hose to the spout on the can, which happened to be the perfect size of the bleeder screw on the clutch line  I think it was $12 or $18 total for the oilcan and 1 foot of line.

I think it was $12 or $18 total for the oilcan and 1 foot of line.

***NOTE**** When reverse bleeding the clutch line, make sure the can is FULL of clutch fluid, and that you EMPTY your clutch master cylinder, or you'll spill @!#$ EVERYWHERE!

ALSO

Pump the oil can at a reasonable rate so you DON'T creat air bubbles as you pump, or you'll just have to do this all over again. This particular oil can has a ball and spring in the pickup so when you release the pump handle, fluid stays IN the pick up and you won't get air in the line, allowing you to re-fill the can if you run out of fluid.

Hope that helps Darren. Hey, did you ever find those videos of Chris' car running? His old thread that got locked 3 years ago had the videos from your photobucket, but i can't view them without your username and password for some reason. Weird.

Thanks a bunch for showing this!!!!!!!

PRND321 Till I DIE

Old Motor: 160whp & 152ft/lbs, 1/4 Mile 15.4 @88.2

M45 + LD9 + 4T40-E, GO GO GO

Quote:

Thanks a bunch for showing this!!!!!!!

No problem, i do what i can to help.

dear god brother what head is that!??!?! its

tiny

reminds me of the sohc head...

All I want... is a little of the good life

z yaaaa wrote:dear god brother what head is that!??!?! its tiny

reminds me of the sohc head...

It's one of those clearwater Brand New 086 heads. Freshly cast

they intentionally leave a lot of meat in the head since 08 heads are prone to thermal shock which cracks the head.

Don't worry though, it's getting P&P'd and worked over to flow properly for the HG2's.

color me lost.... raf's (dohc tuner) new 086 was WAY more opened up than that the way it came from them...

All I want... is a little of the good life

Mine is a clearwater head too. It def had that baby exhaust port. I did port it out quite a bit but think I am going to port it more.

Last 3" UJ pipe finally came in. Recieving it got me back in the mood to touch the car. A couple little things have been done since my last post but i figured i'd save them all up for 1 post versus 4-5 little ones, sooo...

The intercooler is now suspended by it's self

The A/O sperator has been drilled and tapped for a 1/4" barb fitting for the PCV system.

Trans finally back together with GM grey sealant.

and i've been going over the 086 head to see what modifications will be needed to run an LD9 waterneck so i can use the stock coolant system, and i found that on factory 086 heads, where the waterneck seals in the head, there is a slotted hole beside it. On this brand new casted head it's just a drilled hole, so i need to tap and plug the hole so i can use the LD9 waterneck.

That's all for now. Working on the car again tonight. Hopefully pulling the blown engine this weekend.

if i were you i would use the 2.3 fitting that screws into the line hole on the head and then adapt the LD9 line to it....

Anything worth doing is worth over doing.

Anything worth doing is worth over doing.

Nice

~2014 New Z under the knife, same heart different body~

______________________

WHITECAVY no more

2012 numbers - 4SPD AUTOMATIC!!

328 HP

306 TQ

z yaaaa wrote:if i were you i would use the 2.3 fitting that screws into the line hole on the head and then adapt the LD9 line to it....

I don't have a quad waterneck on hand, and figured it'd be much easier to just tap and plug the hole since i have both a tap & plug here at work. That second hole is useless even with the quad waterneck if i were to use it on my engine.

Pretty sure i'd also have to mod a quad waterneck to be able to use it without the thermostat being at the head. Seems like a PITA considering i have everything i need to just plug the hole now. If it leaks, i'll swap waternecks.

Quote:

Nice

Thanks!

im lost... why cant you just use the 2.3 water neck? its better after-all being made from aluminum versus the weak plastic LD9 one that always cracks.

then just modify the LD9 line to work with that fitting. it really wouldnt be that difficult.

as for the thermostat, talk to cory (z's z), i believe he ran the stock ld9 thermostat and didnt use one in the water neck.

Anything worth doing is worth over doing.

Anything worth doing is worth over doing.

z yaaaa wrote:im lost... why cant you just use the 2.3 water neck? its better after-all being made from aluminum versus the weak plastic LD9 one that always cracks.

then just modify the LD9 line to work with that fitting. it really wouldnt be that difficult.

as for the thermostat, talk to cory (z's z), i believe he ran the stock ld9 thermostat and didnt use one in the water neck.

quad4 waterneck

I'd have to buy more fittings to adopt the LD9 cooling system with the quad waterneck. That's more work/money for a worse seal, since it just uses a paper gasket versus the LD9's O-ring design.

Who has had trouble with the LD9 waterneck cracking? I've never heard of that being an issue. Especially since it's so thick. I'll get in touch with Cory since he has first hand experience with it.

well, ive had to replace 3 of them over the years. my dad has at least once in his 00z. they crack around that so beloved o-ring you talk of

the LD9 uses a paper gasket between the water pump and the block and its fine so...

its cool man, do it the way you see easiest.

Anything worth doing is worth over doing.

Anything worth doing is worth over doing.

I use the 2.3 water neck. I don't recall needing to modify very much...but it's been a while.

I have no signiture

If you dont trust the paper gasket, use RTV. I have had the @!#$ty 0-ring fail to many times so I use RTV on my 2.4 outlet.

My 2.3 build will use the 2.3 neck as I dont want to have to deal with any stupid issues.

I think it was $12 or $18 total for the oilcan and 1 foot of line.