are these the bit i shouldget for my own p&p

im trying to get the bits and stuff i need from walmart instead of paying for shipping and such.... thanks\

btw im using a dremel

I don't mean to rain on your parade, but in all seriousness.. I've been reading up on doing my own port and polishing, and really.. If you don't know exactly what your doing there's a good chance your head will flow worse..

Either get some examples of what to do and what not to do, and read about how the air flows, and why certain things are in the head that should not be changed or have someone else do it for you. It takes a long time which is why it's somewhat cost prohibitive but I would do a bit of research before you spend a bunch of time, and in the end have someone tell you that you jacked it up.

-Matt

Edited 1 time(s). Last edited Thursday, May 31, 2007 10:41 AM

-------------------------------------------------------

thanks whitte but ive been around and have read up on this plenty. also have had many thread here about this. i plan on trying on a scrap head first just to get use to the tools, and speeds,bits, etc.

i just want to make sure i get the right parts to work with

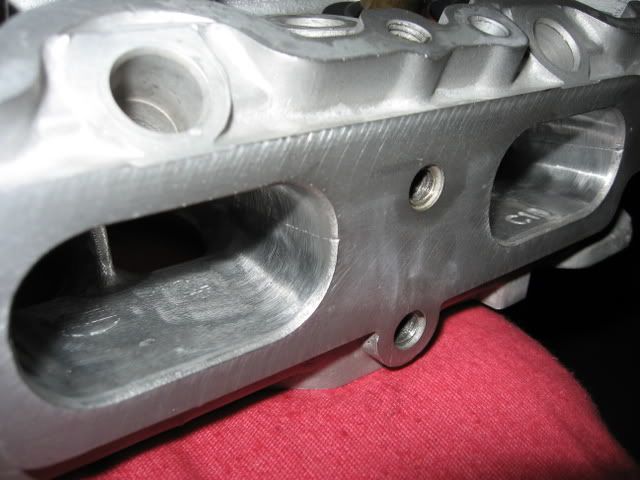

ill try hosting the picture again

hows that?

Sounds good Drake, maybe you could do an instructional write up about porting?

That would be a good read I think, for a lot of people.

Those are the tools I would start with. I would probably use more sanding drums then those material eaters though.

-Matt

Edited 1 time(s). Last edited Thursday, May 31, 2007 11:08 AM

-------------------------------------------------------

Ditch the fist two, they're bad news. Also, add in a couple grinding stones

fortune cookie say:

better a delay than a disaster.

what kind of grinding stones? i didnt look for them but do they have a grade or size?

Grinding stones on an aluminum head!?! In my exsperience aluminum doesn't grind very well, fills the pores in the stone.

this is why i asked before i got started. cause i have not experience. josh what would you recommend? or all the other 2.2 2200 head porters please chime in.

Yeah those stones wont work at all.I got a bit before that coat $15 bucks but works really good on alum.I wish i could tell you witch one it was but its needle like size.

hmmm may have to ask them at lowes

Joshua Dearman wrote:Grinding stones on an aluminum head!?! In my exsperience aluminum doesn't grind very well, fills the pores in the stone.

All the bits fill with aluminum lol. I used WD40 while I was porting, and ground on a steel exhaust manifold to clean the bit when it got clogged with Al (often), but the stones help a lot in between the cutter and sanding rolls.

The grinding stones are pretty obvious when your looking through the bits at the store, they're reddish-brown...get the cone-shaped ones.

Also, pick up the flapper wheels for all your polishing [exhaust runners, combustion chambers (VERY LIGHT PRESSURE)]. They're expensive, but well worth it.

fortune cookie say:

better a delay than a disaster.

really? all of them....I've never had a problem with sand paper filling up with aluminum....unless you talking REALLY fine grit and even then I took more work area then a port job.

Drake: I got nothing for suggestions other than lots of exsperience with metal work....not particularly port n polish work since I've never done it myself. IMO Notec knows his @!#$ and I'd take his suggestions and go with it. If it were me I'd stick to mostly sanding tools and not too much grinding tools, but if you have some spare metal around to clean the bit up with then grinding tools will work ok but you will spend more time cleaning than grinding and your tools will get chewed up trying to clean them rather then getting used up for the greater purpose. The best method I've found to getting good surface finish on aluminum and doing it quickly is using those sanding pads that look the stuff in ebay acution number: 230135813710, those are the flat pads but I've seen them made into the taper type of bits your looking for. BTW, those flat pads in the auction are awesome for smooting out a quad4 intake manifold, fast, easy, and do not get clogged. That last point is my point, if you can find them in the taper like you need then your set.

like notec mentioned just squirt wd40 on the stone before using it and squirt it when it clogs. Bits actually grind very fast and shouldnt be used on aluminum

My suggestions:

Scrap the dremel and get a real 1/4" die grinder.

Get an air powered one, too. Electric cannot change speed easily if at all.

Get a Standard Abrasives deluxe porting kit #260001 ... about $40.

Get a couple of Non-Ferrous Carbide Burrs to do the basic work. Buckeye Carbide was the cheapest but their website is down.

Do not use stones or cartridge rolls to do the base work. They change shape as you work leading to inconsistancy. Only use rolls for light finish work.

Simply sandy some casting marks out of the head does not make it ported.

Investigate other known good heads (read 'expensive') for direction on what to do. Go to a speed shop and look at aftermarket CNC heads. Anything for a v8 should be a good basis for 2.2 work. But always try to start out doing mild or moderate changes. Big changes usually require a few donor heads to be cut apart to verify wall thickness, etc., or permanent mistakes are very likely to happen.

Properly done, any cutting/grinding tool can cut fast. Be careful, go easy, and don't force the tool. Let it cut at its own easy pace.

Don't worry about "making it worse". Odds are that it will at least improve, or worse case, basically stay the same no matter what you do.

Cross buffs with WD40 to lube them are far superior to flapper wheels.

sig not found

Quote:

Get a Standard Abrasives deluxe porting kit #260001 ... about $40.

This is an excellent kit, I bought it yesterday. It also has some very good tips on how to port your head at home. Pick this kit up instead of the individual bits that you have above. Any NAPA store can order this kit through standard abrassives.

"Go Before Show Yo."

CARCUSTOMS.NET, THE BEST SERVICE ON THE ORG!!!

i dont want to order a whole kit to just waste on a scrap head. then have to buy another kit for the actual head.

unless the kit can be used for many diff. heads.

btw: going sat to pick up the junked head. i have no clue what its off of, i just asked them if they had junked heads for a cav, and they said no, then i asked they had any junked aluminum heads and they said yeah. cost a whole $15.

Just any old aluminum head isn't really gonna teach you much of anything of than power tool control.....you need to practice on the deal deal so you can learn from mistakes like running through into the water jackets and such. That will teach you where you need to be careful and where you can really get to porting. If I were you I wouldn't waste my time or tools on just any old aluminum head.

guess ill keep trying to find a head then... i cant seem to find one anywhere

protomec wrote:My suggestions:

Scrap the dremel and get a real 1/4" die grinder.

Get an air powered one, too. Electric cannot change speed easily if at all.

Anything about porting i have read say stay FAR away from Dremels as they can burn up from continious use. Also a nice size air compressor tank will go a long way as well because you dont have to keep waiting for it to refill.

Look on ebay, they have like 100+ dremel bit kits for like $15.

Ive always used different sanding drums, mostly for the fact that the aluminum doesnt stick to them; though they do wear down fast. Id use rougher sanding drums for removing most of the material, then softer grit to kinda smooth things out. Abrasive buffs help to start to polish and smooth out, then use a soft felt bit or one of the flapper wheels and some polishing compound.

Ive never done any heads, but Ive done manifolds and throttle bodies and such. I did a little on my stock plastic 2.4 intake mani by removing some material from the runners and plenum. Plastic was much harder to do than aluminum lol

ive heard it a few times (dont use a dremel) but thats all i have. i dont have a garage, and i dont have an air compressor or a dye-grinder, so thus far im stuck with the dremel. im just learning the internals of the heads and strength of the tools for now, i figure ill practice now and the practice again for perfection then the real thing.

now this could all change if some of you were willing to give me your big nice air compressor, and dye grinders. but till then ill have to deal with what i got.

Hell I live in an apartment building lol, and I still use my dremel for many many things. I love it

i like the dremel cus it gives me nice rpm control over my air tools