Okay, a SBC uses a minimum of 1.25 intake/exhaust valve diameter ratio, higher performance motors using up to 1.36. The LN2 used 1.19...Why do we have such small intake/large exhaust valves? It can't be because it's more efficient, because the LD9 uses a 1.23 ratio.

I'm looking to have some valves cut, and trying to figure out what sizes I want. Comments? Suggestions?

Also, how much room do I need to leave between the two valves since they are angled in when opened? There is .150" when they are seated, and .095" with both valves at .300" lift with stock diameters. Anyone know how to calculate the point at which the valves are at equal lift? I have no idea what stock duration is (probably very close to 200)...lift being .288, lobe seperation 144 IIRC? I really would think you'd need to have some clue of the ramp, but I'm not sure how that is done

This would be so much easier to figure out with an OHC engine

fortune cookie say:

better a delay than a disaster.

Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow. The SBC is at about 77 %, which is why most SBC cams have more intake lift and duration than exhaust. The LN2s are right at 80 %, which is why the cams are most commonly ground with a symetrical pattern. The same is true for (excuse my foul language

) Ford motors.

As far as measuring the valve clearance the only way I know of is to do an actual measurement, here's where the geometry whizes' will come in handy. I know Isky Racing Cams has an article in their catalog and/or online on how to measure the Piston-to-Valve clearance, but I would like to find out how to do the valve-to-valve clearance.

the 2.4 is direct lift

so there is no rocker ratio

MadJack wrote:Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow.

You wouldn't happen to know why this is would you? Just wondering, not opposing. I haven't taken fluid dynamics yet (put it off), so I'm not sure what would go into determining this...

MadJack wrote:As far as measuring the valve clearance the only way I know of is to do an actual measurement, here's where the geometry whizes' will come in handy. I know Isky Racing Cams has an article in their catalog and/or online on how to measure the Piston-to-Valve clearance, but I would like to find out how to do the valve-to-valve clearance.

Well, I guess I could bolt the head back up to the block without crank/rods/pistons, and then rotate the cam until the valves measured at equal lift, then pull the head back off and measure the seperation at that lift...but this would probably be different with a higher lift and longer duration cam anyway, so it wouldn't really help to do it now (although I could get stock and 1.6:1 readings).

[quote=97cavie24ls(JDM&00s/c sedans™)]the 2.4 is direct lift

so there is no rocker ratio

, did you post in the wrong thread? I don't think anyone has mentioned the LD9 other than valve face diameters...

fortune cookie say:

better a delay than a disaster.

OHV notec wrote:MadJack wrote:Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow.

You wouldn't happen to know why this is would you? Just wondering, not opposing. I haven't taken fluid dynamics yet (put it off), so I'm not sure what would go into determining this...

The exhaust gases only have about 80-85 % of the density of the A/Fcharge.

Quote:

MadJack wrote:

As far as measuring the valve clearance the only way I know of is to do an actual measurement, here's where the geometry whizes' will come in handy. I know Isky Racing Cams has an article in their catalog and/or online on how to measure the Piston-to-Valve clearance, but I would like to find out how to do the valve-to-valve clearance.

Quote:

Well, I guess I could bolt the head back up to the block without crank/rods/pistons, and then rotate the cam until the valves measured at equal lift, then pull the head back off and measure the seperation at that lift...but this would probably be different with a higher lift and longer duration cam anyway, so it wouldn't really help to do it now (although I could get stock and 1.6:1 readings).

As far as measuring the V-to-V clearance, just stick the valves in the head and move the out an equal amount from the seat till you they contact. No need to reassemble the head. Just make sure to measure the lift accurately, use a set of calipers.

MadJack wrote:OHV notec wrote:MadJack wrote:Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow.

You wouldn't happen to know why this is would you? Just wondering, not opposing. I haven't taken fluid dynamics yet (put it off), so I'm not sure what would go into determining this...

The exhaust gases only have about 80-85 % of the density of the A/Fcharge.Wait, wouldn't that be the other way around? A gas of lower density would occupy a greater volume (equal mass entering and exiting, cam w/ equal lift and duration), so it would need a greater cross-sectional area to flow...? If the exhaust gases are less dense, they would need a larger exit...?

MadJack wrote:As far as measuring the valve clearance the only way I know of is to do an actual measurement, here's where the geometry whizes' will come in handy. I know Isky Racing Cams has an article in their catalog and/or online on how to measure the Piston-to-Valve clearance, but I would like to find out how to do the valve-to-valve clearance.

Quote:

Well, I guess I could bolt the head back up to the block without crank/rods/pistons, and then rotate the cam until the valves measured at equal lift, then pull the head back off and measure the seperation at that lift...but this would probably be different with a higher lift and longer duration cam anyway, so it wouldn't really help to do it now (although I could get stock and 1.6:1 readings).

As far as measuring the V-to-V clearance, just stick the valves in the head and move the out an equal amount from the seat till you they contact. No need to reassemble the head. Just make sure to measure the lift accurately, use a set of calipers.Right, but when the engine is assembled and running, they will never both see that extreme of a lift at the same moment in time. I need to know at what degree in the cam's actual rotation the valves are at the same lift...that way I can determine how much additional valve head diameter I can run by measuring the current clearance...

fortune cookie say:

better a delay than a disaster.

OHV notec wrote:MadJack wrote:OHV notec wrote:MadJack wrote:Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow.

You wouldn't happen to know why this is would you? Just wondering, not opposing. I haven't taken fluid dynamics yet (put it off), so I'm not sure what would go into determining this...

OHV notec wrote:The exhaust gases only have about 80-85 % of the density of the A/Fcharge.

Wait, wouldn't that be the other way around? A gas of lower density would occupy a greater volume (equal mass entering and exiting, cam w/ equal lift and duration), so it would need a greater cross-sectional area to flow...? If the exhaust gases are less dense, they would need a larger exit...?

It's been a few years since I read up on it, it may be the desity was greater. I do remember that after the combustion process, the properties were changed significantly enough that you only needed the 80-85 % valve sizing to balance the flow. I wasn't the physicist who wrote the article!

MadJack wrote:As far as measuring the valve clearance the only way I know of is to do an actual measurement, here's where the geometry whizes' will come in handy. I know Isky Racing Cams has an article in their catalog and/or online on how to measure the Piston-to-Valve clearance, but I would like to find out how to do the valve-to-valve clearance.

Quote:

Well, I guess I could bolt the head back up to the block without crank/rods/pistons, and then rotate the cam until the valves measured at equal lift, then pull the head back off and measure the seperation at that lift...but this would probably be different with a higher lift and longer duration cam anyway, so it wouldn't really help to do it now (although I could get stock and 1.6:1 readings).

As far as measuring the V-to-V clearance, just stick the valves in the head and move the out an equal amount from the seat till you they contact. No need to reassemble the head. Just make sure to measure the lift accurately, use a set of calipers.Right, but when the engine is assembled and running, they will never both see that extreme of a lift at the same moment in time. I need to know at what degree in the cam's actual rotation the valves are at the same lift...that way I can determine how much additional valve head diameter I can run by measuring the current clearance...

Just to add to the complexity of the measurement, try adding half the additional diameter of the int. and exh. valves and adding the difference between the valves, which would reduce the max lift values. Problem here is that wouldn't take into account the valve angles.

Some one with a CAD program might be better at determining the max valve size and V-to-V interference lift amounts. You would also need to keep in mind the shrouding effect of the close proximity of the valves to each other, the combustion chamber around the valve and the cylinder walls.

Going to this extreme might be alright for a maximum effort race engine, especially for a boosted motor, but for a mostly street driven motor might be a bit over-kill. IMHO, I would just go with the SI 1mm over valves and a good pro P&P. Though, it does make for some very interesting theoretical study.

I think I'm following what Notec's asking. Say the valves are closest when, I dunno, both valves are at .400" lift. Well you know that both intake and exhaust won't see that lift much at the same time. If they're open the same amount at the same time it will be at a lower lift. So you will actually have more V to V clearance than what you'd measure at .400".

My thoughts: You need the exact cam profile, including lobe shape, to determine exactly when the valves are open the same amount. But you can make some guesses using fairly general numbers. If you have cam specs published at .050" and they show some degree of valve overlap, then you can say that both valves will be at least .050" open when they are at the same height. If your cam specs show overlap at "seat to seat," .006", .002", or any other smaller value but not at overlap then you can say both valves are at the same height when they are open between .050" and the seat to seat height. If you have no overlap, then both valves are never open the same amount.

If you don't have the .050" lift specification, you could use the seat to seat and .050" figures and punch them into a dyno simulation program which makes assumptions about the cam lobe shape based on the type of lifter. This program would generate an estimated overlap for you. The problem is that I've found these programs to be quite wrong when you're using a dual profile lobe. The LT4 factory cam which I measured simply can't be entered correctly into Dyno2000. The lobe shape is too different from what the software wants.

To find what you want, you need a "cam checker" or the time and patience to measure the cam profile, in block, with degree wheel and dial indicator. It's not that hard to do... set up degree wheel to indicate TDC and mark lift in 1 degree increments.

Yep, sure would be easier with OHC engine. Anybody ready to go Ecotec yet?

Have fun.

-->Slow

MadJack wrote:OHV notec wrote:MadJack wrote:OHV notec wrote:MadJack wrote:Typically you want an exhaust to be approximately 80-85 % the size of the intake for the closest balance of I/E flow.

You wouldn't happen to know why this is would you? Just wondering, not opposing. I haven't taken fluid dynamics yet (put it off), so I'm not sure what would go into determining this...

OHV notec wrote:The exhaust gases only have about 80-85 % of the density of the A/Fcharge.

Wait, wouldn't that be the other way around? A gas of lower density would occupy a greater volume (equal mass entering and exiting, cam w/ equal lift and duration), so it would need a greater cross-sectional area to flow...? If the exhaust gases are less dense, they would need a larger exit...?

It's been a few years since I read up on it, it may be the desity was greater. I do remember that after the combustion process, the properties were changed significantly enough that you only needed the 80-85 % valve sizing to balance the flow. I wasn't the physicist who wrote the article!

, either way, I get the point, thanks for the info.

slowolej wrote:I think I'm following what Notec's asking. Say the valves are closest when, I dunno, both valves are at .400" lift. Well you know that both intake and exhaust won't see that lift much at the same time. If they're open the same amount at the same time it will be at a lower lift. So you will actually have more V to V clearance than what you'd measure at .400".

Slow's got the idea.

slowolej wrote:My thoughts: You need the exact cam profile, including lobe shape, to determine exactly when the valves are open the same amount. But you can make some guesses using fairly general numbers. If you have cam specs published at .050" and they show some degree of valve overlap, then you can say that both valves will be at least .050" open when they are at the same height. If your cam specs show overlap at "seat to seat," .006", .002", or any other smaller value but not at overlap then you can say both valves are at the same height when they are open between .050" and the seat to seat height. If you have no overlap, then both valves are never open the same amount.

If you don't have the .050" lift specification, you could use the seat to seat and .050" figures and punch them into a dyno simulation program which makes assumptions about the cam lobe shape based on the type of lifter. This program would generate an estimated overlap for you. The problem is that I've found these programs to be quite wrong when you're using a dual profile lobe. The LT4 factory cam which I measured simply can't be entered correctly into Dyno2000. The lobe shape is too different from what the software wants.

To find what you want, you need a "cam checker" or the time and patience to measure the cam profile, in block, with degree wheel and dial indicator. It's not that hard to do... set up degree wheel to indicate TDC and mark lift in 1 degree increments.

Well, the simulation might give me some idea, but there's still a chance for error, and at more than $250 per valve set, I really need to make sure there's no mistake

Unfortunately I don't have the cam specs, and I really have no idea what I'm going to be using either, but there will definately be lots of overlap. I didn't want to start with a cam yet, because I wanted to get the competed head on a flow bench to help determine what the cam was going to need. The evil cycle...cam, valves, valves, cam...

slowolej wrote:Yep, sure would be easier with OHC engine. Anybody ready to go Ecotec yet?

NEVER! If I wanted it easy, I would be building a 1st gen DSM

Besides, I like this stuff, much more interesting than trying to figure out "which blow off valve sounds the best?" and "how much HP will I get from cutting off my muffler?"

fortune cookie say:

better a delay than a disaster.

Quote:

The evil cycle...cam, valves, valves, cam...

Not so bad. Pick a cam. Choose one with big lift and duration #'s. Yes, it's arbitrary. Call the cam grinder, ask them to determine point of equal lift. Then grab head and make measurements.

Well, I'm considering pulling the stock Sunbird 2.0 turbo OHC engine for an Eco engine. $500 for a low mileage Eco gives more bang for the buck than $500 into a 200k mile "old skool" 2 valve OHC lame duck. Then add 17 psi to that engine and all Helsinki will break loose.

And maybe it will be the easy way, but it's ok since the Eco was never in a 2nd gen J.

-->Slow

slowolej wrote:Quote:

The evil cycle...cam, valves, valves, cam...

Not so bad. Pick a cam. Choose one with big lift and duration #'s. Yes, it's arbitrary. Call the cam grinder, ask them to determine point of equal lift. Then grab head and make measurements.

I thought about that, just assuming the largest possible profile, but the biggest effect will come from the LSA. I'm not sure what kind of # I'm going to end up with in that area...and that figure unfortunately can't be arbitrary

slowolej wrote:Well, I'm considering pulling the stock Sunbird 2.0 turbo OHC engine for an Eco engine. $500 for a low mileage Eco gives more bang for the buck than $500 into a 200k mile "old skool" 2 valve OHC lame duck. Then add 17 psi to that engine and all Helsinki will break loose.

And maybe it will be the easy way, but it's ok since the Eco was never in a 2nd gen J.

-->Slow

Well, that's not a bad thing. As long as you're not dropping it in the '93, just can't replace the

.

fortune cookie say:

better a delay than a disaster.

slowolej, I think I see the Light!

Some times it just takes hearing (well seeing) another way to catch on.

BTW, Eco in a 2nd gen, thats unique. I haven't heard of anyone doing that till now. Definitely bumps up the cool factor!

Anyways, OHV notec, your best bet is to find out what cam will match up to your work on the motor, then you can find out the overlap w/ equal lift. Thats the conundrum of building and designing engines; you need this to get that, but you need that to get this!

?

You know what kind of power you'd like to build.

You know what size engine you're using.

You have a fairly good idea what rpm you'll need to turn to make the power you want.

You probably realize the the cam design is pretty well dictated by the intended use. For the power you said you want, you're looking for a high rpm screamer. That condition alone limits cam selection. If it were me, I'd talk with a few cam grinders, maybe run a few simulations, come up with a "worst case" scenario using the cam with the highest point of equal lift. I think you'll find there isn't that much difference between cams at the level you want to be at.

-->Slow

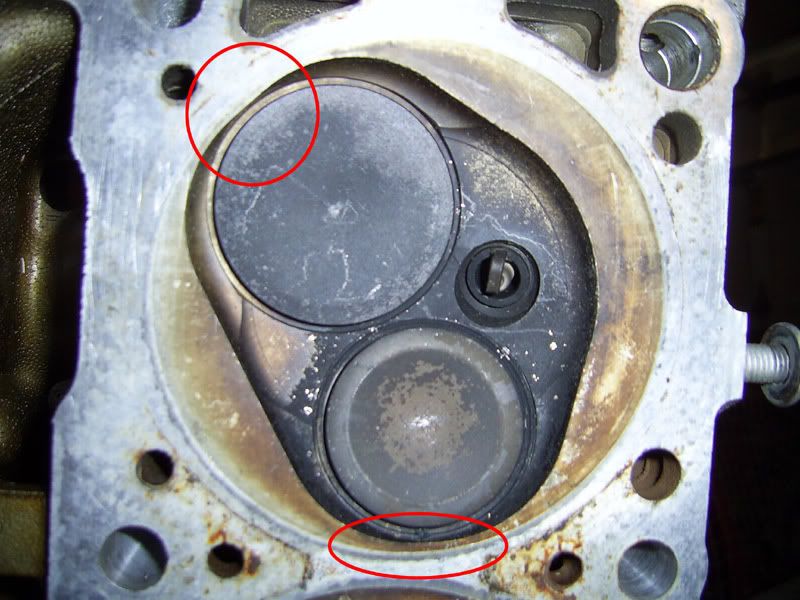

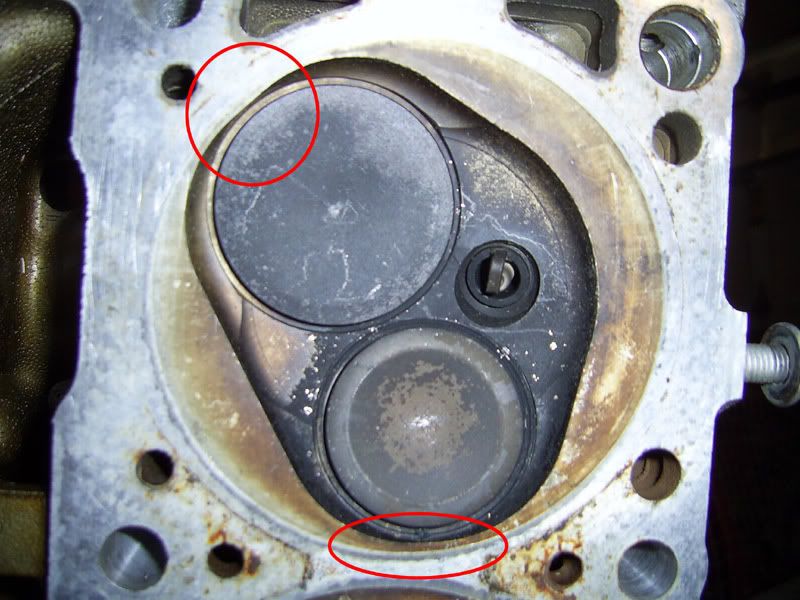

Okay, time to bring this one back from the dead to go a little more into oversized valves.

In order to reduce shrouding, would it harm anything to enlarge the combustion chamber around the valves in the areas that 'hang' over the cylinders?

fortune cookie say:

better a delay than a disaster.

From the pic it looks like that might make the material between the chambers a bit thin but that's just me.

It would make it so the material between the chambers is the same amount as between the cylinders...

fortune cookie say:

better a delay than a disaster.

...

the exact face i get when it comes to engine math

dan

You can go as far as the sealing ring on the gasket. You might have noticed many HGs curve outwrds in the area of the valves, this is to provide more room for the valve and side clearance.

Excellent, exactly what I wanted to hear

I'm looking at +3mm intake and +2mm exhaust. At .100" lift there is .15" clearance between valves. These valves would allow a 33% safety margin in the case that a crazy cam actually has both valves open even more than that.

Also, I've been playing around with that dyno2000 software all day, and it's cool to see how after so much lift or duration, any more is counter-productive. I must say though, the software sucks when using it w/ boost.

Look for another post to be brought back from the dead

fortune cookie say:

better a delay than a disaster.

OHV notec wrote:Look for another post to be brought back from the dead

Funny how that keeps happening! Could it be we keep coming up with more?

Almost forgot, will the valve seats handle that large of a valve or will you need to get bigger seats installed?

I'm assuming it will need new seats (stockers look like they'll take about +1.5mm), but if I ever get to this it won't be a street motor, so hardened seats would be necessary for the rpm anyway.

fortune cookie say:

better a delay than a disaster.

.

.