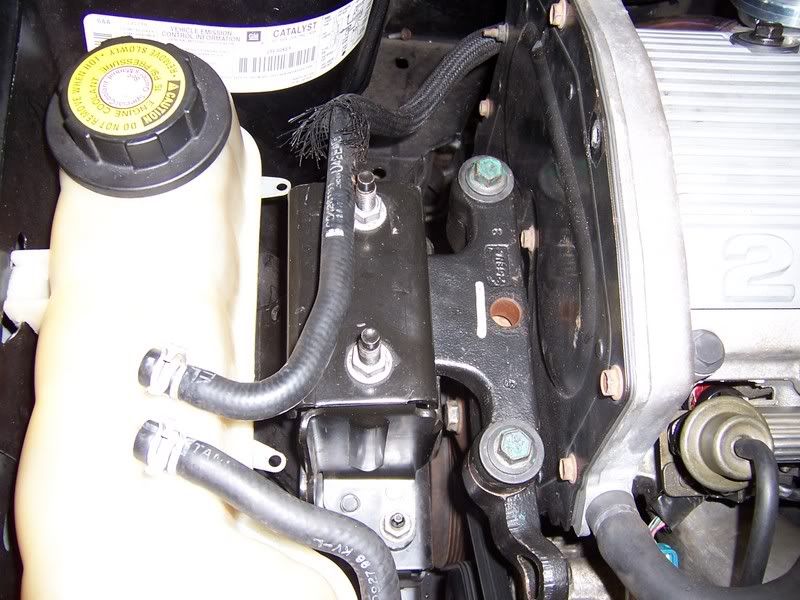

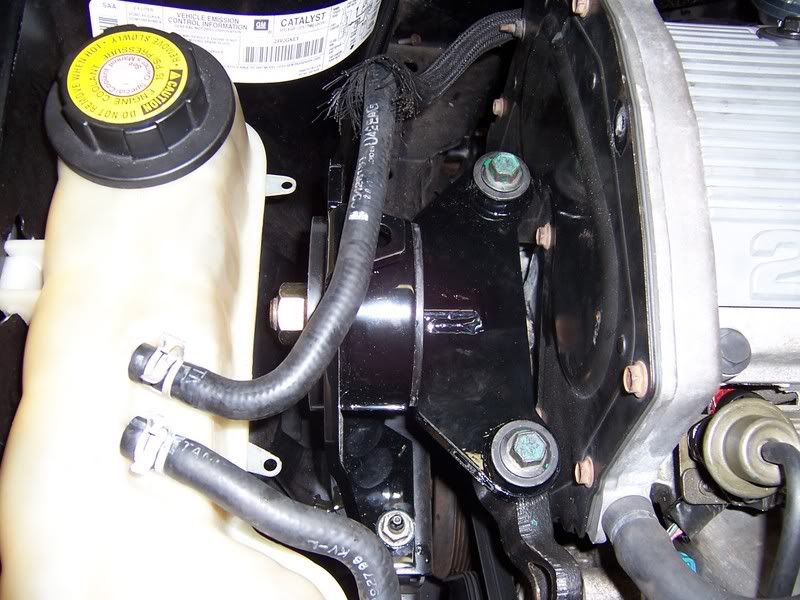

Well today is the day I received the new TTR 2.4L upper motor mount ( Thanks Aaron ). Out of the box the mount was gleaming like gold!!!... Excellent packaging and service!!!....Vincent Morris and I did some measuring and modifying of the stock eco mount to fit the 2.4 motor, but after we figured out what had to be done we told Aaron and he already had the design layed out but just needed some final measurments.

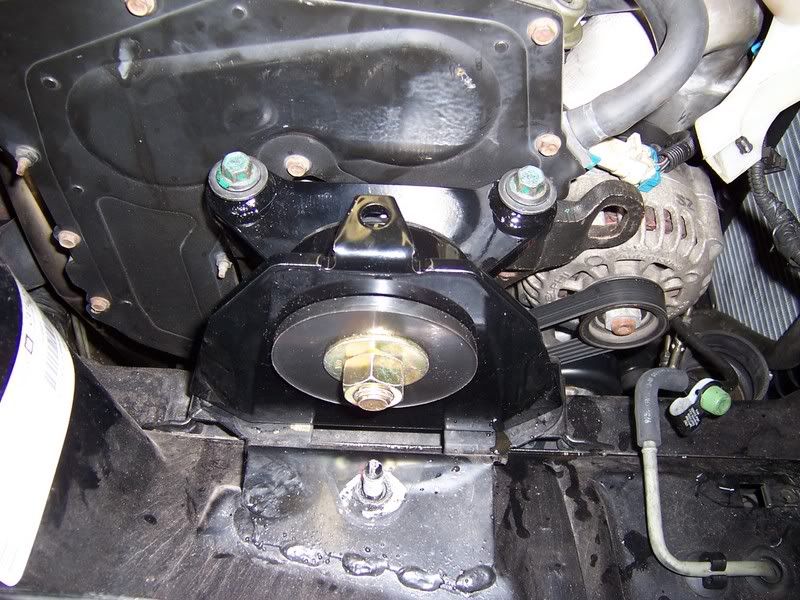

Low and Behold the TTR Upper Motor Mount for the 2.4L engine was born.

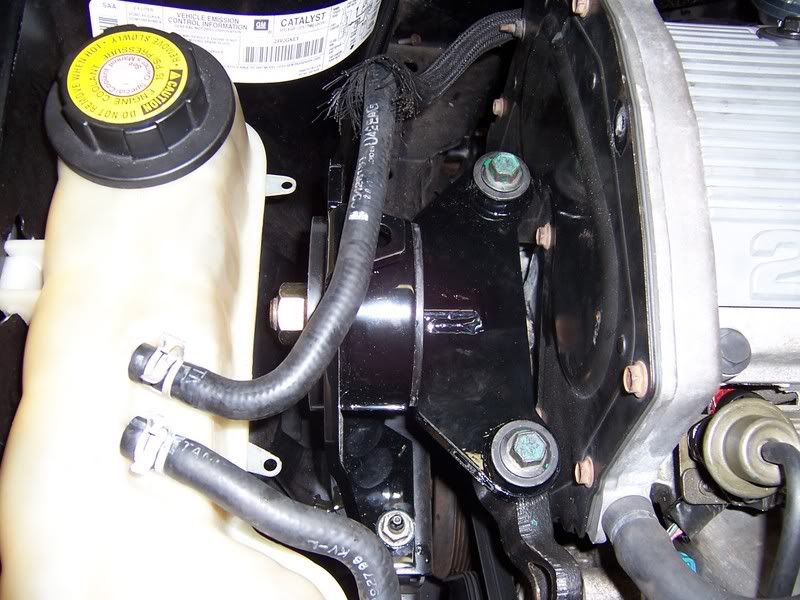

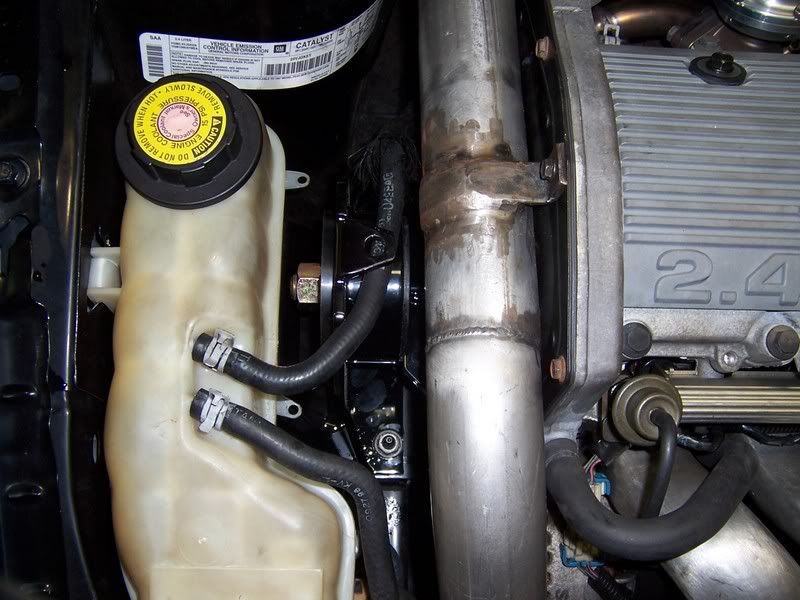

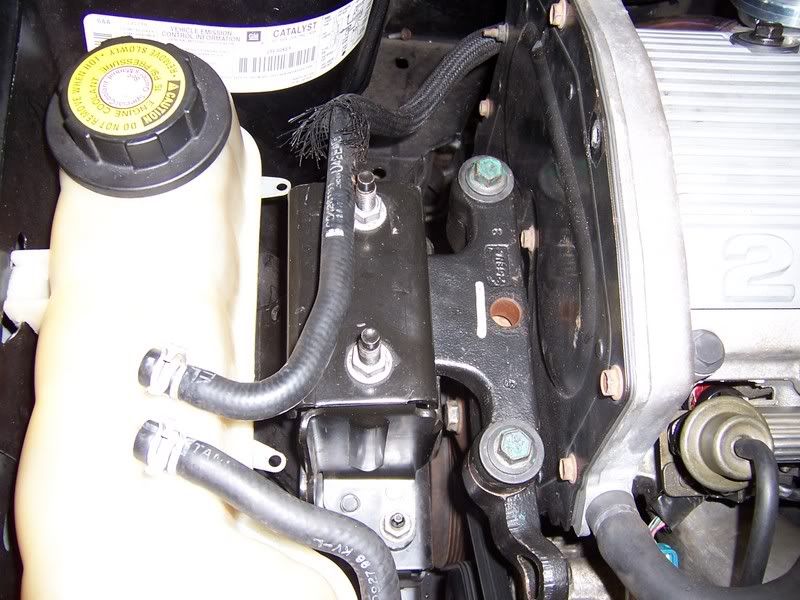

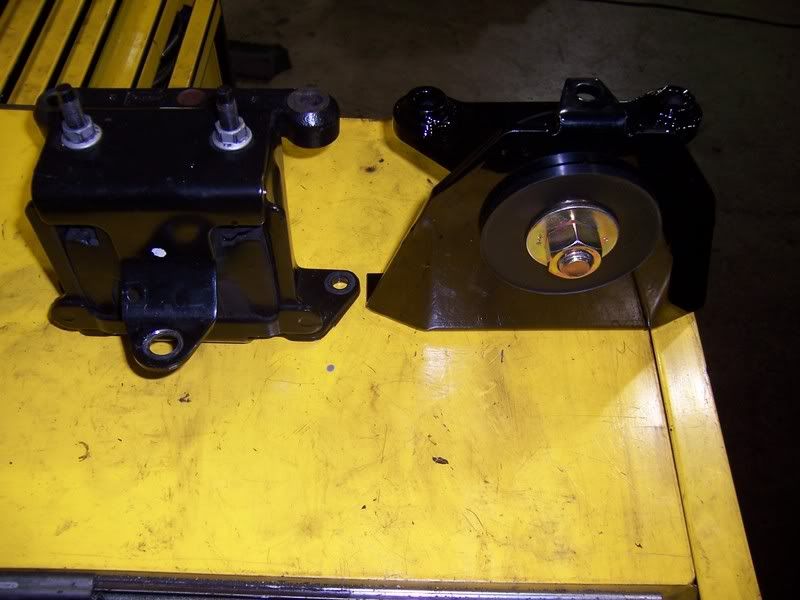

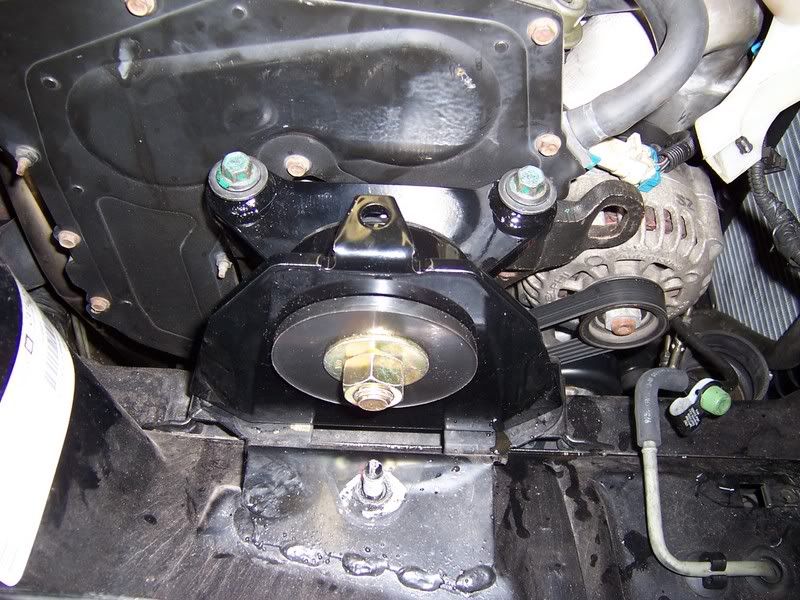

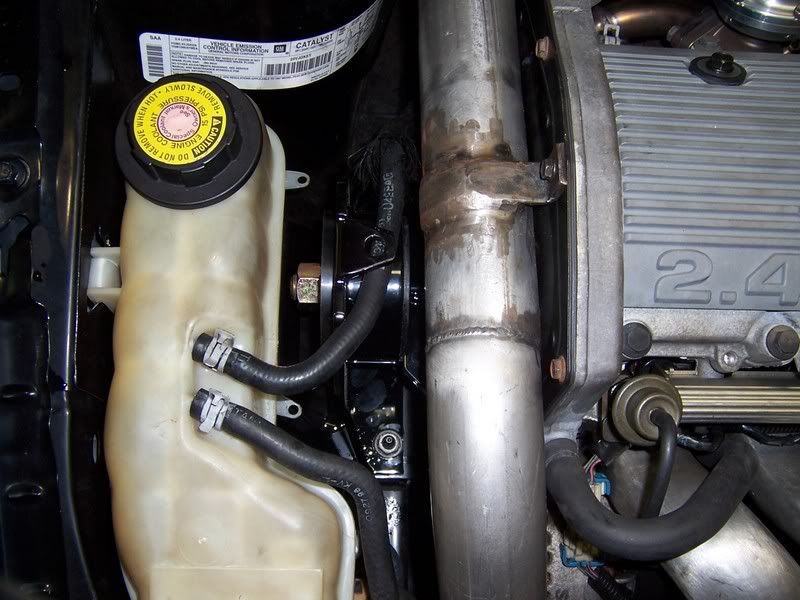

Aaron has produced an excellent upper mount for the 2.4L...I took some install pics and comparison pics as well....

Now the directions are damn near the same as the Eco mount.....just support the engine and unbolt the existing crappy mount and install your new TTR mount............

The mount has the great advantage of limited /and or no wheel hop.....even though it was raining when I went on the test drive, I was still able to tear through a few gears and had no wheel hop what-so ever....

Before the mount I would have wheel hop in dry and wet weather.....not no more..

The Motor mount also has the added benefit of no body vibration.....NONE....the car seems to be calm and no vibration unlike the RKSport upper insert and lower mount

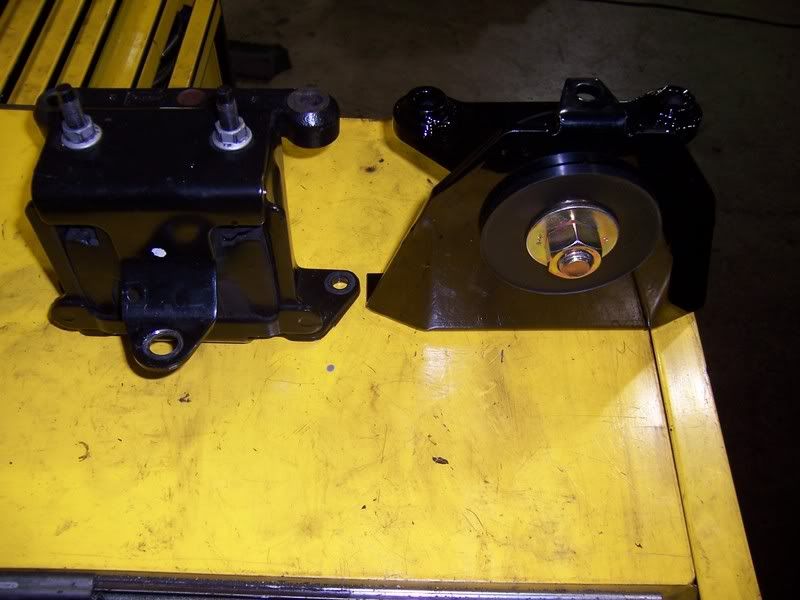

Comparing the two mounts that I have, the OE mount with the RKSport insert (after 5-6 years) is fatigued and sagging....The TTR mount is very solid and don't see a problem with sagging at all. Now even thought I had the insert for 5-6 year and it is the original OE mount it never seemed to be a stiff as the TTR mount..

When you do install the Mount do not use and Impact wrench on it....You may/will cracked the powder coating off.....I did and have learned my lesson...But i have touch up paint to fix it..

Well, I cant take it anymore....On with the pics

TTR FTW!!!!!!!!!!!!!!!!!!!!!!!!!!!!!.................Thanks Aaron!!!!!!!

All desiging/fabrication was done by Aaron....Vincent and i just took some final measurements for him...And am lucky to be part of testing the mount with the others...Enjoy!!

I apologize for crappy puncuation...i always hated english....

Im glad we planned that day so fast. Convo followed...

Me:Hey lets get together next week sometime and work on that mount to get it fabbed up.

Phil:ok, how about next wed.

Me: That should work

Phil: Cool

Me:actually what you doing now?

Phil: nothing.

Me: want to do it now?

Phil:yeah sure why not?

Me: Ok Im on my way.

Side note. Most may not have to remove Charge Pipes

I drove 2 hrs worked on it for a while and 2 hrs back, definately looks good. TURBO TECH RACING FTW

Edited 2 time(s). Last edited Monday, October 16, 2006 8:27 PM

it doesnt use the 3rd mounting hole??????

I may run 18s, but I can do your taxes in 10 seconds flat.

Machzel08 wrote:it doesnt use the 3rd mounting hole??????

no.....i see no need for it either....the upright plate in which the bushing sits in very ridgid and i dont seeing the mount becoming weak .......

it doesnt need the 3rd mounting hole. the plate is 1/4" thick i believe. so there for it is very stiff and no need for it

where do i get one!!!!!!

"Boost tuning"....... have you had your 8 PSI today?

future name of the winter shop!!!

Nice.

And such a simple design when looked at side by side.

What did you use to support the engine?

-M

Remember....syringes go in the RED waste basket.

i want one so bad.....too bad im short on cash

looks good though man, nice work...notice a big difference?

* * BIG FOR SALE POST * *

* * BIG FOR SALE POST * *

Mastin wrote:Nice.

And such a simple design when looked at side by side.

What did you use to support the engine?

-M

I just took a jack stand with a block of wood and set it under the engine...actually i set it on the lower engine bracket that the lower dog bone style mount goes to (the one around the oil pan). But you could take a regular jack with a block of wood and do it that way to....i did it with the jack stand because it was on a lift and easier for me.

that explains where the black/black went , lol

TTR FTW for upper mounts

and hopefully auto trans mounts

awsome job guys.......... see how simple of an install that is? I bet even my one handed ass can put it in (might need a photographer

Curt?)

anyway, looks awsome!!!

SPD RCR Z -

'02 Z24 420whp

SLO GOAT -

'04 GTO 305whp

W41 BOI -

'78 Buick Opel Isuzu W41 Swap

Machzel08 wrote:it doesnt use the 3rd mounting hole??????

Yes, but the third hole would help with lateral support. I guess I wait on the mount.

Still Great Design.

PRND321 Till I DIE

Old Motor: 160whp & 152ft/lbs, 1/4 Mile 15.4 @88.2

M45 + LD9 + 4T40-E, GO GO GO

phil- why does your upper mount plate look like you welded it on? did u do an engine swap or something?

also...im anal, wouldnt it be posible to make a strap out of steel and bolt that bolt on the back of the TTR mount to it and then bolt the 3rd mounting location down as well?? im not doubting anything of the mount, i have full confidence, i'd just feel a bit better knowing that 3rd bolt was secured.

White 98'Z-alive n kickn

Black 97'Z-down for the count

Z YAAAA wrote:phil- why does your upper mount plate look like you welded it on? did u do an engine swap or something?

also...im anal, wouldnt it be posible to make a strap out of steel and bolt that bolt on the back of the TTR mount to it and then bolt the 3rd mounting location down as well?? im not doubting anything of the mount, i have full confidence, i'd just feel a bit better knowing that 3rd bolt was secured.

This has been looked at during the design phase. The stock mount is made from only 12 gauge which is about .105" material thickness. Our mount is created from over 2 times as thick .250" steel. Also, GM did away with the 3rd bolt in 2002 with the Ecotec. It is structurally not needed; it provides no front to back support, being at the pivot point (center of the mount). In addition, there is zero side-to-side force on the mount with our design, which is the only force it would help with.

We could put on a "strap" but it would be no benefit and just make the mount more expensive.

-Aaron

www.TurboTechRacing.com

Performance Parts For Cavalier, Sunfire, Cobalts and More!!!

One last thing.

What's the weight diff?

About the same?

-M

Remember....syringes go in the RED waste basket.

Just a thought and not trying to hike up any production costs in any way, but what about the structural integrity to where the two bottom bolts are? I would think that would put undue stress on them when not using the third as a lateral support.

michaelj1967 wrote:Just a thought and not trying to hike up any production costs in any way, but what about the structural integrity to where the two bottom bolts are? I would think that would put undue stress on them when not using the third as a lateral support.

Again, the back bolt does not offer any support in movement of front to back of the car (movement direction of the engine) It is there for side force (which there is basically nothing) The stock mount is made from 12 gauge, where the TTR one is from 1/4". We did hours of FEA (Finite Element Analysis) and determined the stress and fatigue points. There is no reason for this, being the TTR mount is not the GM mount design.

Where are you getting any side to side force the engine doesn’t push sideways? Also, again look more at the GM Ecotec mount, GM never used a 3rd bolt and they are the same size bolts on the frame of the car. This is because the GM Ecotec mount is closer to the TTR mount structural shape.

Trust us we did the work there is no need for it.

Edited 1 time(s). Last edited Tuesday, October 17, 2006 9:00 AM

-Aaron

www.TurboTechRacing.com

Performance Parts For Cavalier, Sunfire, Cobalts and More!!!

Mastin wrote:One last thing.

What's the weight diff?

About the same?

-M

The weight is almost the same. Within 1-2 lbs.

-Aaron

www.TurboTechRacing.com

Performance Parts For Cavalier, Sunfire, Cobalts and More!!!

Lookin good.

- 93 mph in the 1/8 mile

Member of J-Body Of Michigan.

Turbo Tech Racing wrote:michaelj1967 wrote:Just a thought and not trying to hike up any production costs in any way, but what about the structural integrity to where the two bottom bolts are? I would think that would put undue stress on them when not using the third as a lateral support.

Again, the back bolt does not offer any support in movement of front to back of the car (movement direction of the engine) It is there for side force (which there is basically nothing) The stock mount is made from 12 gauge, where the TTR one is from 1/4". We did hours of FEA (Finite Element Analysis) and determined the stress and fatigue points. There is no reason for this, being the TTR mount is not the GM mount design.

Where are you getting any side to side force the engine doesn�t push sideways? Also, again look more at the GM Ecotec mount, GM never used a 3rd bolt and they are the same size bolts on the frame of the car. This is because the GM Ecotec mount is closer to the TTR mount structural shape.

Trust us we did the work there is no need for it.

Sorry for my ignorance on these issues and not questioning the quality, because just from seeing it it looks many times better than the original, I was more wondering if the strength of where the mount is mounted to, that's what I should have clarified.

Again sorry if any offense.

No offense taken; we would rather clarify, than to ignore and not give our support to something we spent a lof of time designing; helping the community is why we are here

Edited 1 time(s). Last edited Tuesday, October 17, 2006 9:13 AM

-Aaron

www.TurboTechRacing.com

Performance Parts For Cavalier, Sunfire, Cobalts and More!!!

Turbo Tech Racing wrote:No offense taken; we would rather clarify, than to ignore something we spent a lof of time designing; helping the community

Thanks, now if I only had the money, I'd definitely would get one, I do like the design.

If i remember from my upper mount, that third bolt just helps supports that "cap" that under which the insert goes. It definitly doesnt seem needed. As for the bracket that holds my A/C line, is there a way to make that work with the hole thats on the top of the mount, or am i to tuck it under like in the photos?