Tomorrow I will be porting my head. I have been porting cylinder heads for a quite some time now. You can see my work in my profile shortly. Anyways, I was wondering if

when your head was ported, did they take out that casted piece out of the exhaust. It comes up from the short turn on the bottom of the exhaust runner. If you were looking at the head on the engine it would be on the bottom of the runner. I was just wondering because a small runner like that wouldn't seem to need all that design to it.

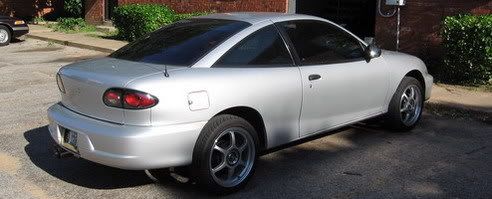

nullC:\Documents and Settings\HP_Administrator\My Documents\My Pictures\Chevelle Cavalier-025

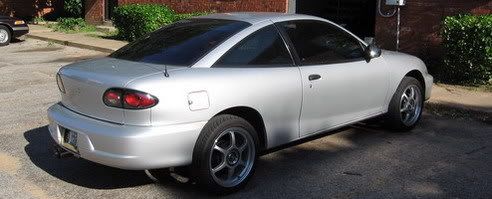

nullC:\Documents and Settings\HP_Administrator\My Documents\My Pictures\Chevelle Cavalier-061

nullC:\Documents and Settings\HP_Administrator\My Documents\My Pictures\Chevelle Cavalier-021

Just some examples of my work. Trying to show you guys what i do.

C:\Documents and Settings\HP_Administrator\My Documents\My Pictures\Chevelle Cavalier-021

yum upload the pics to photobucket or anothe hosting website. just trying to help out man.

Hey thanks man i gave up, I couldn't figure that out and i've been trying for 1hr and 1/2 now.

So what do you think. Leave the vane in or out. Personal Opinion. If you were in my shoes.

Since that build guide was written, Jim Feuling did a bunch of work with anti-reversion designs in exhaust systems. You could remove the vane and use a cone similar to the Feuling design if you have a good grasp on how it works. As far as the head goes, the ports themselves are actually quite efficient compared to some older designs. I posted the port volumes, and the flow numbers for a stock head have been posted in the past. Porting these heads isn't just a matter of opening up the inlets and outlets to match gasket dimension imo (not that you're planning to do that, but some people think that's what "porting" means).

The runner has all that design because it was very advanced at the time it was built. Remember the design of these heads is now over 20 years old. I haven't set a 98+ 2200 head next to a 2.2 head to see what they changed. But I think it's a statement about the 2.2 head that GM didn't make any changes to the design other than smaller valve stem diameters for over 10 years. If there had been a way to easily improve it, the powertrain engineers would likely have implemented the changes first chance they got.

-->Slow

someone please post a pic of the vane

sig not found

The "vane" is a ridge in the floor of the port, about 1.25" long, which follows the port and directs flow from the valve to the manifold. The OHV build guide shows 'em, but the quality isn't so good.

http://s120197345.onlinehome.us/2literOHVbuildup.pdf

(Thanks again PJ for hosting this!)

I'll dig up a high res scan tonight if no one posts a real picture first.

-->Slow

That is the vane, the piece that sticks up in the middle

And that is my vane so far

This is a stock casted one

And this is what ive done so far to the lower intake

Well, what do you all think?

I cant tell from the pics how it would affect the general taper and transition of the port.

But my initial instinct is to get rid of them.

I have never seen a head with any sort of protrusion used in any form of racing or true performance engine.

I would guess that the designer of the head was consulted for that GM guide, and believing he had the most revolutionary breakthrough idea ever with that dam, recommended that it be kept no matter what.

sig not found

The '98+ head has rectangle intake ports and slightly smaller exhaust ports. Looking at either head I'd say that they arerather well modeled after the big-block chevy heads ( Oval or rectangle ports were used on BBC heads, depending on if the intent was for horsepower or torque apps. ) All BBC heads used ovaluar exhaust ports and splayed valves in a heart-shaped chamber that had a slight offset twist relative to the cylinder bore vertical centerline. So I figure, if you know to port a BBC head, just treat it like one and remember what Mad Jack said about the vane. Jack?

Go beyond the "bolt-on".

MadJack wrote:I see the vane working similar to the flat side of the D-Shaped exhaust ports of the LT4 heads(which have a vane also!)...

I have no direct info on LT4 heads, but I did a web search and even found some cutaway views of the exhaust ports and I see no vane at all. SO I have to say the is no vane on lt4 heads either.

I stand by my original statements. Anything directly blocking the flow needs to go... unless it will totally, incredibly screw up port volume (the port is way bowed out to make up for the lost volume).

sig not found

Well, im leaving the vane in the exhaust, but i am tapering(more pix to come) so that it is more "aerodynamic" so that it should help more in the upper rpms. I am doing a lot of bowl work and porting around the guide but most of the intense porting is being done to the intake. On the 2.2OHV up until 98 it came with the cast aluminum two piece intake. I believe it to be better in design than the 98'-02' except for the throttle body. It does need a lot of work though, it is very rough and out of shape. The casting marks dont seem to make the right shape. Anyways when i get done with them i will show everyone how it looks. I dont doubt that it will look good but i am worried about how good it will work. I hope all my stock stuff can handle it. Here is the updated list:

96' 2.2 OHV

Bored .50mm(.020)

Zero decked block

Head milled .025

New Valve springs

Crane Roller Rockers 1.6

Head ported

Intake ported

32 Angle valve job

Valves polished and backcut

Any thoughts!

Robert Helms wrote:96' 2.2 OHV

Bored .50mm(.020)

Zero decked block

Head milled .025

New Valve springs

Crane Roller Rockers 1.6

Head ported

Intake ported

32 Angle valve job

Valves polished and backcut

I've seen a couple very disappointed LN2 owners who spent a lot of time/money for a ported head. You won't see the benefits with a stock cam profile.

fortune cookie say: better a delay than a disaster

fortune cookie say: better a delay than a disaster

protomec wrote: I have no direct info on LT4 heads, but I did a web search and even found some cutaway views of the exhaust ports and I see no vane at all. SO I have to say the is no vane on lt4 heads either.

I stand by my original statements. Anything directly blocking the flow needs to go... unless it will totally, incredibly screw up port volume (the port is way bowed out to make up for the lost volume).

Here's a photo of the LT4 head from the GMPP Parts Catalog, you can see what appears to be the vanes in the exhaust ports. (This is from a '97 catalog, the actual image is only 2 3/4" across.)

MadJack wrote: ...it's there to keep the exhaust velocity up on the short side radius, which is the slowest moving part of the exhaust port...

The exhaust gases flow to the top of the port when released from the combustion chamber(wanting to flow in a strait line) and a vortex is created just after the short side radius. This vortex hinders the velocity of the exhaust gases, reducing the scavenging effect and allowing reversion in the port. The vane is placed in the slowest moving part of the runner, typically where the vortex is formed, keeping the velocity up and reversion down to a minimum. The D-Shaped port is another method of accomplishing this.

There is a difference between volume and velocity. Most all production heads have sufficient runner volume for street or street/strip motors, it's in the valve throat, bowl area, short side radius and valve guide that are the flow obstructions. The runners, on a N/A motor, usually only need to be port matched and smoothed, leaving the vane there to keep the velocity up. On boosted/nitrosed applications, you need more volume, velocity isn't as important, unless you need a turbo to spool-up quickly, which can be corrected with shorter cam exhaust durations. On these applications, you aren't using scavenging to help fill the chambers, but compressed air/fuel charges(nitrous oxide does the same thing, except the oxygen is compressed into an extremely cold stable liquid) being forced into the combustion chamber, so removing the vane can help increase the volume of exhast expelled, though you will lose some port velocity.

Keeping the vane on a N/A motor keeps velocity up to help scavage the spent exhaust gases and help draw in a fresh air/fuel charge resulting in more power. On a boosted/nitroused motor, you want to expell more volume of spent exhaust gases, velocity isn't as important, so removing the vane would provide slightly more benefit than keeping it.

Those are actually the exhaust valve stems, not vanes cast in the head. See how polished they are and perfectly in line with the valves? Valve stems for certain.

MadJack, you seem to know your stuff. I have already reshaped my exhaust into a kind of D shape. I did this so that i could try to raise the runner. I cut out the top of the port out to the gasket line and also widened it on the side to the same point. I did not cut down on the short side. All i did there was smooth it and sharpen the vane. The guide work is where i shine. That is where i spend some time cutting it down to the actual guide. Also i widened the bowl and raised the top of it too. Im trying to finish the heads right now. All i have left is the exhaust bowls and guides. I will have pix up immediately after. I want full opinions good or bad when i do post them.

Notec, do you think the 1.6 ratio rockers will be enough to see some use of the porting. Even though it is only .07 more than stock.

What you're seeing is the valve stems. If you look carefully you can make out the bottoms of the guides. No vanes in LT4 port.

-->Slow

Robert Helms wrote:Notec, do you think the 1.6 ratio rockers will be enough to see some use of the porting. Even though it is only .07 more than stock.

Highly doubtful. A cam regrind is less than $200, a very good investment.

fortune cookie say: better a delay than a disaster

fortune cookie say: better a delay than a disaster

Where is the best place to get my cam reground or what about a new cam. Does anyone make a cam with a center line at 108-110.