Well there should be a way to lower my cavy without spending a ridiculous amount of money.

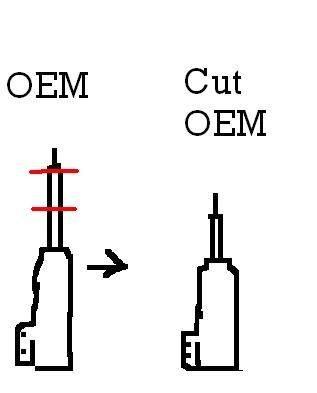

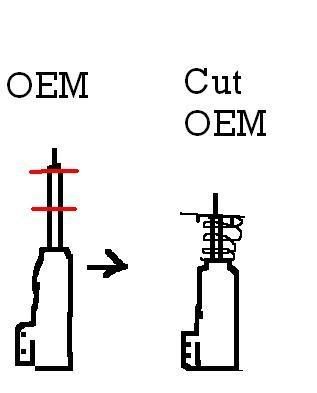

I searched, but nothing came up, my question is: can I cut the bolt which holds the mount in place to the same degree of lowering inches of my Rk sport springs, then weld the bolt head (tip with thread) back on. Second question, does this piece contain pressurized air or is it simply just metal? Pics...

I actually give you bonus marks for creativity. That plan actually seems plausible, and could reduce the compression stress on the strut, possibly increasing the life span of the strut on lowered springs.

Then I consider how difficult it would be to prevent the welded joint from being a weak point, and eventually breaking, probably while trying to make an emergency maneuver to avoid a toddler that chased a ball onto the street.

And just because you might get the stock struts to last longer, doesn't mean they won't still ride like crap because they can't manage the higher spring rate.

Shop Manuals, Brochures:

www.kenmcgeeautobooks.com

Geeky wrote:Then I consider how difficult it would be to prevent the welded joint from being a weak point, and eventually breaking, probably while trying to make an emergency maneuver to avoid a toddler that chased a ball onto the street.

right. its a clever idea but the fact you have to depend on that weld is not good. cutting a piece and welding it back on is not as strong as 1 continous solid piece.

$500 for struts is not, I repeat NOT a "ridiculous" amount for a suspension setup.

1989 Z24 Convertible - Dust Covered

2006 tC - Dust Covered, but driven more

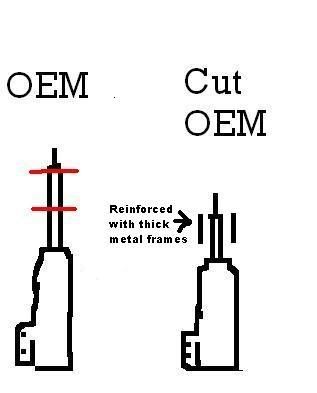

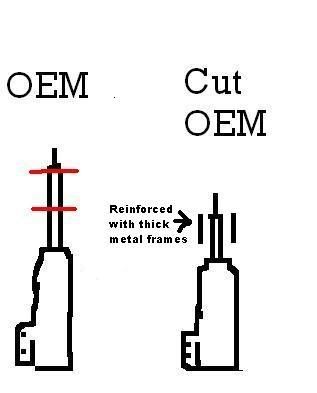

Hey how abou re-inforcing the weld with metal bars (small frames) around the area of weld. Basically, first welding the the connections together, then sandwhiching it around with thick metal frames (welded of course). This would act as reinforcement connected below and above the cut zones.

"I actually give you bonus marks for creativity. That plan actually seems plausible, and could reduce the compression stress on the strut, possibly increasing the life span of the strut on lowered springs." ----My point exactly, the oems are very cheap, but maintain good feel, plus since everything is acurate, and porbably off by a few degrees (a little grinding cant fix), this would be a real cheap mod. So there would no worries of blown shocks, since the shocks were cut to your after market spring lowerinfg rate, thus the shock and your desired spring act as OEM.

Pics..

Problems I still see with your plan are:

1) Unless the threaded tip reattached perfectly straight, it could stress the mounts and itself once tightened down and promote premature failure.

2) While you may be sucessful in cheating to get the strut back to its proper "stock" home position and reducing compression stress, you still have an underqualified strut trying to manage a much stiffer spring. You say the OEM struts "maintain good feel", but I think you'll find many would disagree when it comes to lowering springs.

3) I'm not an expert welder, but is seems to me that you have a hard time doing any extensive welding on the strut shaft without running a risk of overheating and damaging the main strut assembly. While this is fairly easy to deal with, you're still modifying a safety-critical part, and most likely doing something stupid at best and illegal at worst.

4) I don't know if this is possible, but it would be less of a hack if you could find a machinist who could re-mill a new set of threads 2" down the shaft. Probably big bucks though, even if doable.

5) You make a good point about asking whether the shafts are solid. I know the "good" adjustable struts have adjustments for the valving at the top of the shaft, but I don't know if anything occupies that space on the stock struts.

6) Pay some money for decent struts, and you get something that should outlast the car, still be around if you get another J, and keep decent resale value if you want to sell them down the road. Good (removable) aftermarket parts are a better investment than the car is in the first place.

7) I'm out of points... but please don't.

Shop Manuals, Brochures:

www.kenmcgeeautobooks.com

Geeky wrote:And just because you might get the stock struts to last longer, doesn't mean they won't still ride like crap because they can't manage the higher spring rate.

In the end, this is what it will always come down to. Yes, the factory struts may last longer but the ride quality would be atrocious. You NEED stiffer struts to compensate for stiffer springs.

No, you cannot alter the stock struts in any way, shape or form to compensate for lowering springs. </thread>

1989 Z24 Convertible - Dust Covered

2006 tC - Dust Covered, but driven more

Alfredo turbokav wrote:Well there should be a way to lower my cavy without spending a ridiculous amount of money.

Two words: Sand bags.

Since it sounds like you're probably going to go through with this plan anyways, do your best not to cause any 911 calls. And even if you pull it off, I'm sure any report of success will probably send the countless cheapskates on this board running off to make their own half-assed attempt at welding. Someone is going to regret it sooner or later.

Edited 1 time(s). Last edited Tuesday, June 05, 2007 10:35 AM

Shop Manuals, Brochures:

www.kenmcgeeautobooks.com

"In the end, this is what it will always come down to. Yes, the factory struts may last longer but the ride quality would be atrocious. You NEED stiffer struts to compensate for stiffer springs." -- true, how about using oem replacements that can withstand stifer springs, like gabriels or tokito? Who knows; maybe they will ride good or close to oem specs. The only way im finding out, is if I try it.

I'll call my invention (patent pending)-"the sandwiched midget." lol

The re-inforced are of weld well be grind a bit to be smooth and painted to block any moisture which would create rust.

Anyhow, thanks for the comments and suggestions, though sending the shocks to be re-milled for new thread at a shorter level sounds interesting and would be a safer route. The problem is that I dont know a mill shop around here (Chicago, IL), but if a stick with my plan, I'm sure I will save alot of money.

Why not do your suspension properly, and just buy some aftermarket struts?

This seems like alot of work and risk to save only a small amount of money...

umm,

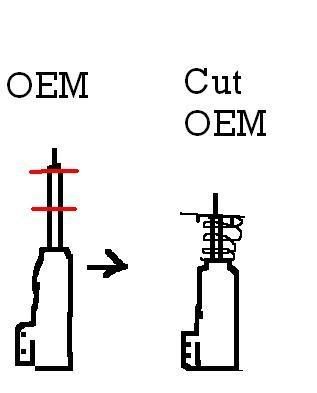

if you reinforce the shock, wont it NOT fit into the housing when compressed, so it would be bottoming out on the bracing, without having made any travel at all.?

Well the weld spots and reinforcements would be toward he upper level before the the thread bolt begin. The reinforcements should not be more than 1.5 inches long and thickness would not matter so as long as it is not interfering with the spring action. I'll calculate the amount of travel needed for the shock to fully function/retract and compress. I doubt shocks travel all the way down to the tip, being that the spring would not allow such a compression, unless you fell of a cliff or ran into an unusual speed bump measuring 2 feet vertically.

ahahaah oh man.... got to be A 16 year kid who just got his licence... im glad i never cheaped out on any thing when building my car up... not worth it at all do it properly and pay a bit more 1 time.... or do it cheaply and do it multiple times and possibly break more things and have to pay alot more... trust me man dont cheap out on any thing on your car .. thats 1 reason Jbodies have a bad rep for being cheep crap cars.... is kids dont take care of them and they break down... i drove the @!#$ out of my car for 3.5 years and it was boosted from 18,000kms and still boosted now @ 52,000kms (in a different car), and it never broke down on me once but i maintained it very well fixed things when they needed it right away (not leave it till more stuff breaks) and didnt cheap out on any parts and it ran very well up untill last summer when i was hit... now the engine is still going strong in my sisters car still boosted too... and suspension .. man thats your safty / others who are in the car...

The First Twin Charged jbody

blue car (R.I.P) - 240whp @7psi..

silver car - 305whp 315lbs.tq @15psi (91 Octane) or 420whp & 425lbs.TQ @20psi (94 octane+Alcohol Injection)

All dynos run on a Mustang dyno

The First Twin Charged jbody

blue car (R.I.P) - 240whp @7psi..

silver car - 305whp 315lbs.tq @15psi (91 Octane) or 420whp & 425lbs.TQ @20psi (94 octane+Alcohol Injection)

All dynos run on a Mustang dyno

Alfredo turbokav wrote:

Since you're absolutely insisting on whipping this dead horse, how will your "brilliant" solution solve the problem that you still have not addressed the issue of stock compression and rebound rates on a (now weakened) stock strut? You're still not accomplishing anything other then inventing a halfassed solution to a problem that could be solved for under $500.

1989 Z24 Convertible - Dust Covered

2006 tC - Dust Covered, but driven more

ZlineDavid wrote:You're still not accomplishing anything other then inventing a halfassed solution to a problem that could be solved for under $500.

I'm pretty sure that's exactly what he was trying to accomplish -- A half-assed $50 alternative to a $500 solution.

Shop Manuals, Brochures:

www.kenmcgeeautobooks.com

Tokicko struts can be had for under $300. If you can't afford that, you can't afford to lower your car. And all this douchebaggery about altering stock struts that are notoriously crap to begin with is no better than Skippy McRicer riding around on chopped coils.

1989 Z24 Convertible - Dust Covered

2006 tC - Dust Covered, but driven more

if u cant afford a suspension then dont lower it. i dont think this hobby is for you!

Joey Baggs (Eazy716) wrote:if u cant afford a suspension then dont lower it. i dont think this hobby is for you!

exactly that... suspension is probably one of the cheaper things you can do (besides in take) so its probably in your best intrest to leave the car alone and move onto modle air plans or somthing... or wait till your budget can afford to do it right..

The First Twin Charged jbody

blue car (R.I.P) - 240whp @7psi..

silver car - 305whp 315lbs.tq @15psi (91 Octane) or 420whp & 425lbs.TQ @20psi (94 octane+Alcohol Injection)

All dynos run on a Mustang dyno

The First Twin Charged jbody

blue car (R.I.P) - 240whp @7psi..

silver car - 305whp 315lbs.tq @15psi (91 Octane) or 420whp & 425lbs.TQ @20psi (94 octane+Alcohol Injection)

All dynos run on a Mustang dyno

Quote:

but if a stick with my plan, I'm sure I will save alot of money.

you would save even more money by not doing it at all. but if you do you will get $75 for your car after something fails and you crash.

my car is stock height, i can't afford to lower it properly so it rides of completely stock suspension.

but A+ for creativity

http://registry.gmenthusiast.com/images/my2005cav/my%20car%20the%20bash.jpg

I have taken stock struts that had stock springs with only 15k on them, compressed the shaft and fluid would come out (not after many times, just once). Factory struts sucks on our cars.

FU Tuning

FU Tuning

I would use "better" shocks in the future, but for now I'm just testing this project. Of course if you decide you want a better feel for the ride, you'd go with gabriels, KYB HP, etc.. (for a budget)

Well I'm kinda worried that the welds on the damper shaft might warp with heat or somehow bend. So i searched and found a company that sells replacement damper shafts. And from the looks of it would it be possible to remove the oem damper shaft? Looks like it's held down by some sort of pin. Does anyone know the exact measurements of our 2.2 95-2002 shock and strut damper shafts? Hopefully i find a shaft that can bolt/pin on on our shocks/struts, and measured to fit along with the Rk sport springs.

http://www.tamiyausa.com/product/item.php?product-id=40546

Oops! disregard that site, it's for RC cars, but you get my point.